Cetim announced as early adopter of Desktop Metal Shop System

May 26, 2020

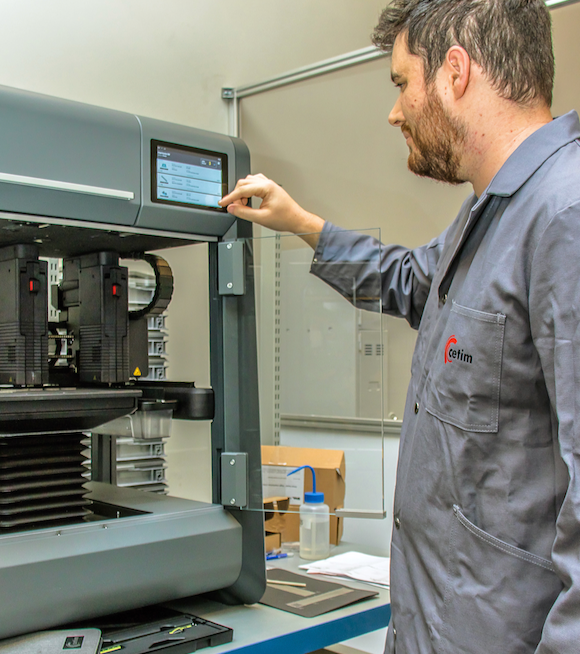

Cetim, the Technical Centre for Mechanical Industry, based in Cluses, France, and Desktop Metal, Burlington, Massachusetts, USA, have announced that Cetim, which works closely with industrial companies to help identify market opportunities and facilitate innovation and technical progress, will become one of the first adopters of the new Desktop Metal Shop System™, a metal Binder Jetting system designed for machine and metal job shops.

The move follows Cetim’s installation of a Desktop Metal Studio System at its Cluses facility. Using both the Studio System, designed for the rapid prototyping and low-volume production of metal AM parts, and now the Shop System, Cetim’s customers in aerospace, oil & gas, automotive and other industries, are expected to be able to explore new, advanced solutions for their manufacturing needs – from low-volume prototyping to mid-volume runs of complex metal parts.

“As the demand for metal AM continues to grow, it is challenging for many of the mechanical industry companies we work with to identify the right solution that meets their needs and then to implement it in an effective and cost efficient way,” explained Pierre Chalandon, Cetim’s Chief Operating Officer.

“Desktop Metal technologies with both the Studio System and new Shop System completes our Additive Manufacturing machines park,” he continued. “From a general point of view, metal Binder Jetting technology is promising for a large part of our clients. Desktop Metal’s solutions portfolio covers the full metal product lifecycle, which is complementary to our experience on sintered material and finishing operations.”

In addition to the implementation of both the Studio System and Shop System, Cetim and Desktop Metal reported that they plan to collaborate on a variety of research initiatives, including design for metal AM, post-processing and finishing techniques qualification, workflow optimisation and materials development, among others.

The Shop System, launched during Formnext 2019, is said to enable shop owners to take advantage of affordable, high-quality Binder Jetting technology to build end-use metal parts at high speeds, to a high quality and at high productivity. With Shop System machine prices starting at $150,000, the machine is expected to enable shop owners to eliminate many of the constraints previously seen with conventional manufacturing methods like CNC machining, and tap into new opportunities to reduce costs and increase revenue.

“When it comes to empowering industrial companies with the Additive Manufacturing technologies of the future, Cetim is truly one of the leaders in Europe,” commented Ric Fulop, CEO and co-founder, Desktop Metal. “We are excited to partner with Cetim as one of the first customers for our ground-breaking Shop System, and are eager to collaborate with Cetim on our shared efforts to change the way that companies manufacture around the globe.”

Cetim operates with a range of different platforms and associated partners, covering almost all direct and indirect Additive Manufacturing technologies including Laser Powder Bed Fusion (L-PBF), Wire Arc Additive Manufacturing (WAAM), and Binder Jetting (BJT). The centre is also strongly involved in the international normalisation of metal Additive Manufacturing, and coordinates AFH, the initiative Additive Factory Hub which aims to innovate, develop and integrate AM to address the key industrial and economic challenges.