Catamold evo: BASF launches its next generation feedstock system at World PM2016

December 8, 2016

Germany’s BASF SE, the market leader in feedstock for Metal Injection Moulding, announced its next-generation MIM feedstock system at the World PM2016 Congress and Exhibition, Hamburg, Germany. The system, called Catamold® evo, improves on the flowability of the feedstock, thereby allowing for more complex and challenging shapes to be moulded. The new evo line represents an evolution of the company’s well-known Catamold feedstock system. The formulation retains its compatibility with existing Catamold based debinding and sintering equipment and signals BASF’s commitment to its widely-used POM-based catalytic process.

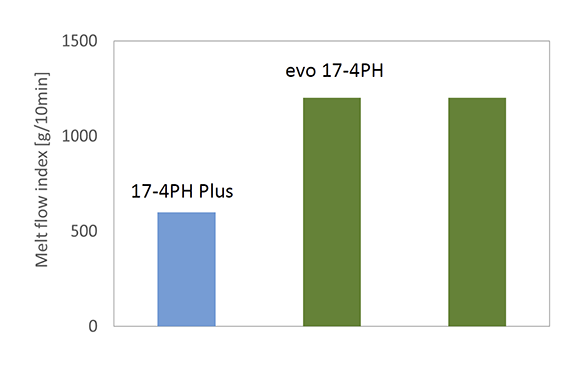

Dr Sven Fleischmann, Global Product Manager Catamold, told PIM International, “The new Catamold evo series is the next generation of Catamold feedstocks and is based on an improved formulation. This allows our customers in various industries improved production efficiency in extended application fields.” Fig. 1 shows the melt flow index of Catamold evo versus the standard Catamold material.

Fig. 1 BASF’s new Catamold evo feedstock offers improved flowability over the original system

The first Catamold evo materials are being launched in Q4 2016 and are reported to include Catamold evo 17-4PH, Catamold evo 316L and Catamold evo 304 stainless steels. Low alloy steels are scheduled for launch in 2017. BASF stated that target applications for the new feedstock system in the 3C sector include connectors for consumer electronics, smartphone frames and bodies and SIM card trays. In the automotive industry target applications were identified as rocker arms, levers and gear shift fingers.

BASF, headquartered in Ludwigshafen, Germany, is the world’s largest chemical company with 2015 revenues in excess of €70 billion. The company’s Catamold feedstock system transformed the fortunes of the MIM industry when it was launched nearly thirty years ago. In 2012 the company announced plans for a dedicated MIM feedstock production facility at its Kuanyin site in Taiwan and today this plant has a production capacity in excess of 5,000 tons per year.