Bodycote becomes first company in Europe to pass MedAccred audit

April 20, 2016

Bodycote has announced that its facility in Derby, UK, has received MedAccred accreditation. MedAccred, administered by Performance Review Institute, is an industry managed approach to ensuring critical manufacturing process quality throughout the medical device supply chain. Bodycote Derby is the first facility in Europe to earn the MedAccred accreditation.

Bodycote has announced that its facility in Derby, UK, has received MedAccred accreditation. MedAccred, administered by Performance Review Institute, is an industry managed approach to ensuring critical manufacturing process quality throughout the medical device supply chain. Bodycote Derby is the first facility in Europe to earn the MedAccred accreditation.

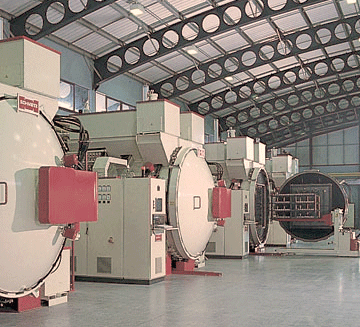

Bodycote Derby offers heat treatment and Hot Isostatic Pressing (HIP) services to the medical device and implants markets for the UK, Ireland and Europe. MedAccred establishes stringent consensus audit criteria based on industry and specific OEM requirements that ensure compliance and quality. Adherence to these requirements leads to greater process discipline, operational efficiency and ongoing improvement which results in higher quality and performance.

Joe Pinto, Executive Vice President and Chief Operating Officer of the Performance Review Institute, the organisation which administers the MedAccred program on behalf of the medical device industry, sent his congratulations to the team at the Bodycote Derby facility. “We are delighted that Bodycote has the honour of becoming the first company to receive an accreditation from MedAccred in Europe.

To be the first in anything demonstrates a high level of foresight and commitment to a long term strategy. The MedAccred audit is challenging and in achieving accredited status, Bodycote’s Derby facility has proven it has the capability to meet and exceed the requirements of its medical customers. The entire team should be proud of their success.”