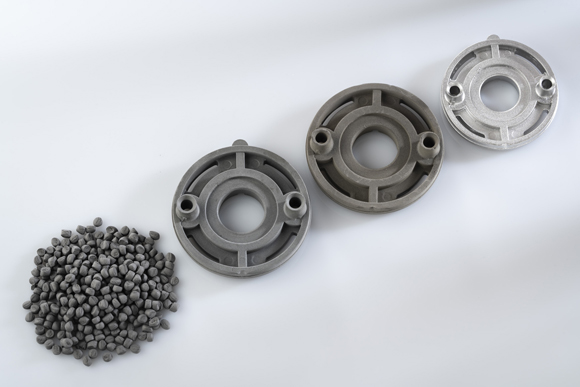

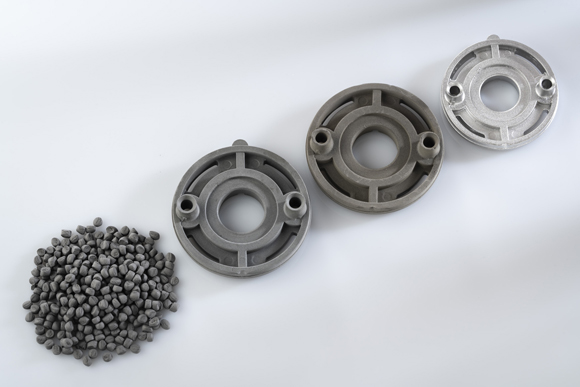

BASF launches new Catamold motion 8620 feedstock, embracing a move to pre-alloyed, water atomised powders

May 19, 2021

BASF SE, the market leader in feedstocks for Metal Injection Moulding (MIM), has expanded its range of feedstock offerings with the release of Catamold® motion 8620 (AISI/SAE 8620, DIN 1.6523, UNS G86200), a low alloy steel well suited to applications such as high-performance automotive components.

Catamold motion feedstocks are produced with pre-alloyed water atomised powders, rather than the more conventional blending of carbonyl iron powders and a master alloy. Whilst the master alloy approach of mixing highly alloyed powders with pure iron powders to produce a wide variety of low alloy carbon steels and stainless steels is well established in the MIM industry, an increased number of producers offering pre-alloyed atomised powders, in parallel with a streamlining of alloy portfolios, are making the use of pre-alloyed powder in Catamold motion more competitive.

Catamold motion 8620 offers the same properties as the established Catamold 8620, including chemical composition, final density, porosity and microstructure, however this new material brings improvements in processability as well as mechanical properties. Identified potential applications for Catamold motion 8620 include eRocker arms for cylinder deactivation in car engines, contributing to a reduction in NOx and CO2 emissions.

A technical report on the processing and properties of Catamold® motion 8620 will be published in the June 2021 issue of PIM International magazine.