AIM3D’s Voxelfill principle overcomes inhomogeneous strength issues with cross-layer filling strategy

October 31, 2022

AIM3D GmbH, Rostock, Germany, has developed a new process for sustainably improving the strength properties of an additively manufactured component. The company’s patent-pending Voxelfill technology is said to overcome inhomogeneous strength issues of the layer-based build process, increasing the cost effectiveness of its Composite Extrusion Modelling (CEM) AM process, a form of Material Extrusion (MEX).

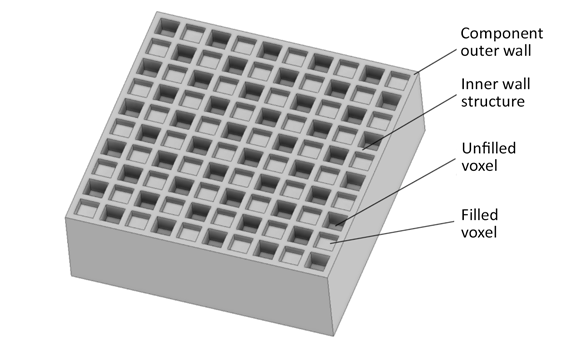

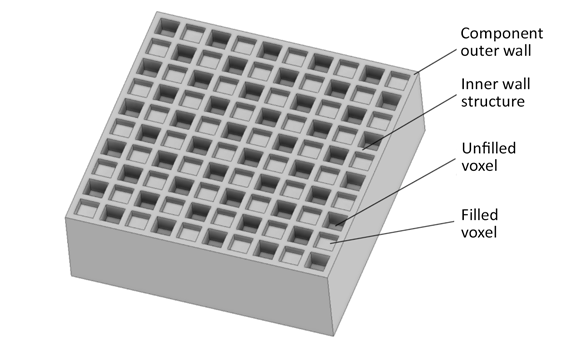

Voxelfill can be used for multi-material components and is suitable for constructing AM components using plastics, metals and ceramics. With the Voxelfill approach, components are no longer created exclusively in layers, but utilise cross-layer filling by using so-called voxels as volume areas. To do this, the component contour is first created as usual as the basic structure using one or more webs of the extruded material. A lattice pattern is created inside the component, which defines the boundaries of the volume elements to be filled, similar to cavities.

This structure of voxels to be filled is said to resemble the honeycomb in a beehive. The Voxelfill strategy comprises two process stages. First, generation of a lattice structure: the CEM system repeats this structure up to a defined height of the volume elements, then at this point, the previously created cavities (voxels) are filled by injecting thermoplastic material with the extruder. The second stage is the filling of the voxels, however, when the volume areas are filled this does not include filling all voxels in one plane. By shifting the volume elements halfway up the voxel, a kind of ‘brick-like bond’ is created in the component, resulting in the yield line being offset.

This reportedly results in a large increase in strength and also improves the elasticity of the components in the Z direction. In addition, the introduced volume elements greatly reduce the Additive Manufacturing time for fully filled components and thus significantly increases the cost-effectiveness of the CEM process.

Variations of the Voxelfill strategy with the CEM process enable the use of various materials, where hybrid multi-material solutions with different Voxelfill materials and different materials for the contour/structure of the inner walls become possible. This way, the material properties can be customised, explains AIM3D. Defined component weight, damping properties, elasticity or changes to the centre of gravity can be tailored to the application. By selectively filling only certain volume chambers (selective densities), component properties could be influenced in a targeted manner on the basis of FE simulations.

With Voxelfill it is possible to only fill the areas of a component that are absolutely necessary for the flow of forces. As a result, from the outside, these components look like conventional parts, and can also benefit from applying finishing processes. At the same time, however, the AM process is carried out with reduced material and weight.

Clemens Lieberwirth, CTO at AIM3D, stated “Of course, the Voxelfill process is particularly suitable for 3D printing of plastics and fibre-filled plastics, but it is also suitable for 3D printing of metal and ceramic components using the CEM process. In general, there are advantages due to the higher build speed and cross-layer filling.”

AIM3D will be exhibiting at this year’s Formnext, taking place in Frankfurt, Germany, November 15–18. In addition to showcasing its Voxelfill technology, it will also mark the commercial launch of its ExAM 510 Additive Manufacturing machine introduced in the beta phase at last year’s Formnext.