formnext 2018: Alliance MIM highlights opportunities for the industry

May 22, 2018

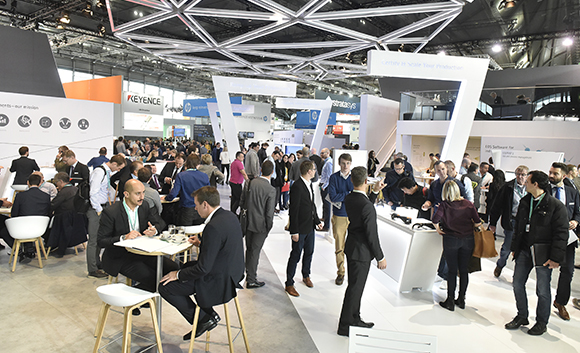

In three years, formnext has more than doubled in size, attracting over 20,000 visitors and covering nearly 30,000 m2 of exhibition floor space in 2017 (Courtesy Mesago Messe Frankfurt GmbH)

Germany’s Mesago Messe Frankfurt GmbH is looking to add Metal Injection Moulding technology to the scope of its formnext exhibition series, dedicated to the “next generation of manufacturing technologies.” The event series, one of Europe’s fastest-growing trade fairs, was launched in 2015 with a primary focus on industrial Additive Manufacturing. Within three years it has more than doubled in size, attracting over 20,000 visitors and covering nearly 30,000 m2 of exhibition floor space in 2017.

The event’s international, industrial-focused audience includes a significant proportion of visitors who are seeking metal powder-based AM solutions, be they Powder Bed Fusion technologies or ‘MIM-like’ binder and extrusion-based systems.

Visitors to formnext 2017 (Courtesy Mesago Messe Frankfurt GmbH)

Jean-Claude Bihr, General Manager of French MIM producer Alliance MIM SA, attended formnext in 2017 and told PIM International that he immediately saw the potential overlaps for the MIM industry. Alliance is now confirmed as an exhibitor for 2018. Bihr stated, “From feedstock extrusion to binder jetting, MIM-like technologies are the answer to the long-standing barrier of tooling cost and development time.”

“These processes are fast and very versatile and, except for the shaping method, they are metallurgically exactly like MIM, thus the name MIM-like,” he continued. “Alliance MIM is therefore developing these technologies – both in-house and in collaboration with equipment suppliers – in order to be able to deliver from one to one million parts, with the first parts in less a than a week.”

Injection moulding machines at Alliance MIM (Courtesy Alliance MIM SA)

Bihr added, “This is why we believe that MIM-like technologies are a door opener for MIM technology. MIM-like technologies make MIM flexible and fast, whilst MIM makes MIM-like technologies scalable. The perfect association! Unlike Powder Bed Fusion processes, MIM-like technologies can be a solution not only for prototyping or very small series. They are also for small production batches, perhaps up to 2,000 units. As such, they are an ideal way to develop a series part at lower cost, ensuring a smooth transition between early production step and full-scale production by MIM.”

MIM-like technologies are a door opener for MIM technology. MIM-like technologies make MIM flexible and fast, whilst MIM makes MIM-like technologies scalable.” – Jean-Claude Bihr, General Manager, Alliance MIM SA.

“Because MIM and MIM-like processes share the same densification mechanism in the same furnace run, what is qualified for MIM may also be qualified for MIM-like processes. The powder is the same, just the way to shape is different.”

Whilst MIM powder suppliers are already well-represented at formnext, it is believed that there is much potential for MIM part producers to gain a greater degree of exposure by taking advantage of the appetite amongst visitors for advanced metal powder-based manufacturing processes. Inovar Communications Ltd will once again be promoting PIM International from its booth at formnext 2018, alongside its other titles, Metal AM and PM Review.