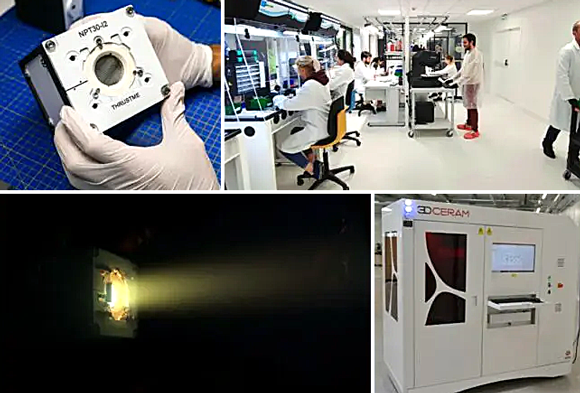

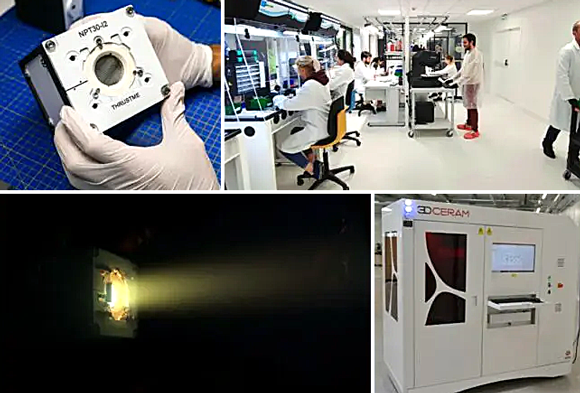

3DCeram and ThrustMe partner for ceramic space components

July 24, 2023

3DCeram, Bonnac-La-Côte, France, has been selected as a supplier to ThrustMe, a space propulsion company based in Verrières-le-Buisson. ThrustMe has recognised the potential of ceramic materials for use in numerous applications and reportedly selected 3DCeram for their expertise in ceramic Additive Manufacturing to help overcome the limitations found in more traditional manufacturing techniques and materials.

“The decision to adopt 3D printing technology for manufacturing a specific part in our thruster was driven by a number of factors that emerged from an extensive research process,” stated Elena Zorzolli Rossi, ThrustMe Product Manager. “Primarily, the space industry often requires the production of complex shapes that cannot be easily obtained through traditional machining methods. At ThrustMe, we don’t talk about only the complexity but also the miniaturisation, a critical requirement in the development of our products. In such cases, 3D printing offers a transformative solution by enabling the creation of specific designs with the precision we need.”

“Moreover,” she continued, “the versatility of 3D printing technology allows us to swiftly iterate and refine designs without incurring significant costs or lead times. Traditional manufacturing processes often involve the creation of moulds or tooling, which can be time-consuming and expensive. With 3D printing, we can rapidly produce prototypes and iterate on designs with minimal setup time, facilitating a more agile development process and accelerating our time to market.”

ThrustMe evaluated various factors, including those relating to the harsh space environment that they have to endure – such as vacuum and extreme temperature ranges – and the specific features of the iodine plasma propulsion system, such as energetic fluxes of elementary particles, secondary emission, intense sputtering and reactive ion etching. Ceramics were selected based on their thermal and chemical stability.

“Another vital characteristic that weighed heavily in favour of ceramic was its wide range of thermal conductivity,” Rossi added. “The efficient transfer or isolation of heat is crucial in our components, as it helps to guide the thermal fluxes effectively and prevent overheating or overcooling. Ceramic materials exhibit an excellent range of conductivity properties, enabling selective heat transfer and ensuring optimal performance in our products.”

“Additionally, the electric properties of ceramic played a significant role in our material selection process. Our components require a material that can effectively isolate and protect against high-voltage electrical breakdowns. Ceramics possess exceptional electrical isolation properties, making it an ideal choice to meet our stringent requirements in this aspect.”

Rossi concluded, “Looking ahead, the future prospects of the New Space era are promising. The ongoing development of technological advancements will continue to drive down the cost of space access and enable more ambitious missions. Accelerating innovation, we are advancing our understanding of the cosmos and improving life on Earth.”

Arnaud Roux, Sales Representative of 3DCeram, shared, “On 3DCeram side, we take pride in our collaboration with Thrust Me as 3D printed ceramic components have been successfully sent into space, marking a significant milestone in the application of Additive Manufacturing. We believe that this successful deployment of 3D-printed ceramic components in space serves as a testament to the immense potential of Additive Manufacturing. It signifies a new era where complex and customised parts can be efficiently produced, surpassing traditional manufacturing limitations.”

“We believe that sharing this milestone achievement provides a great example of the real-world applications of 3D printing. This significant step forward not only validates the viability of 3D printing as a production tool but also inspires us to reach further and unlock the vast possibilities that lie ahead.”

Download PIM International magazine