Zircoa releases first Mg-PSZ feedstock for Ceramic Injection Moulding

December 5, 2022

Zircoa GmbH, a German subsidiary of US parent company Zircoa Inc based in Wiesbaden, has released its first feedstock for Ceramic Injection Moulding. While the company primarily manufactures zirconia refractory products used in high-temperature applications, it also has a well-established portfolio of advanced zirconia ceramics.

The engineered ceramic components – based on Zircoa’s own, in-house manufactured zirconia powder – are said to have several beneficial characteristics, including wear, corrosion, impact and fracture resistance, as well as the ability to withstand high temperatures and harsh liquid/gas environments.

Parts wherein zirconia powder is utilised include:

- wear parts

- battery tools

- fluid flow control

- oil field supply

- electrical

- machine parts

- grinding blanks for machinery

- sensors

- spray nozzles

- valve linings

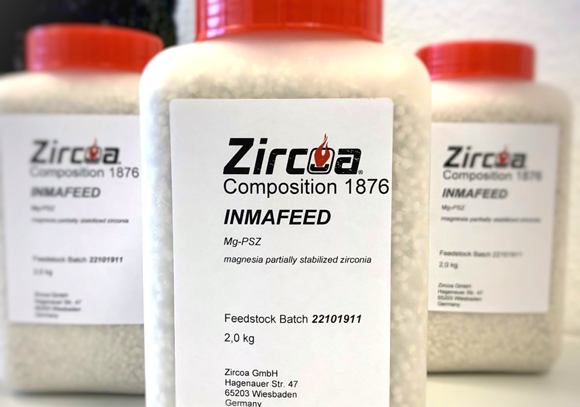

Zircoa’s raw materials are the ceramic basis for the company’s latest ceramic feedstock development. The first of these is the magnesia-stabilised zirconia (Mg-PSZ) Composition 1876.

The Mg-PSZ feedstock was produced together with Inmatec Technologies GmbH, with the thermal plastic binder being the waxy Inmafeed. This binder system, which is already established as an industry standard, is reputedly easy to inject and enables environmentally friendly debinding.

The company added that its zirconia compositions are also conceivable as a basis for future CIM feedstocks.

For further information please contact Tobias Schmidt ([email protected]).