TRIDITIVE launches metal Additive Manufacturing platform based on Ultrafuse feedstock

November 16, 2018

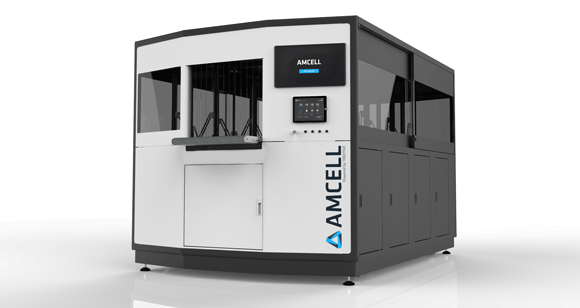

The AMCELL metal Additive Manufacturing system uses BASF’s Ultrafuse 316LX filament (Courtesy TRIDITIVE

TRIDITIVE, an Additive Manufacturing machine maker based in Gijón, Spain, has launched the AMCELL®, a hybrid and automated Additive Manufacturing machine said to be capable of producing up to 10,000 green parts per month using BASF’s Ultrafuse 316LX filament.

Enabled by its control software and remote monitoring, the integrated system is aiming to make Additive Manufacturing a viable solution for high volume manufacturing, 24/7.

According to TRIDITIVE CEO Mariel Diaz, “The green parts printed with AMCELL® using BASF’s metal filament solution meet the geometric and surface quality requirements for mass manufacturing of final parts. The controlled build chamber environment in the AMCELL® and its optimised extrusion process achieve part porosities similar to those that are typically obtained from metal injection moulding technology (MIM)”.

BASF’s Ultrafuse 316LX filament is a metal-polymer composite comprising austenitic stainless-steel type 316L powder. Tailored to existing, high throughput MIM industry standard catalytic debinding and sintering, final metal parts can be produced in high quality.

AMCELL’s automated manufacturing of large batches and the use of Ultrafuse 316LX is said to greatly ease material handling processes by eliminating potential hazards inherent to other metal powder AM processes. The automatic load and consumption control of Ultrafuse 316LX filament spools allow the system to operate largely unsupervised during the whole production process and reduces human labour and intervention to a minimum.

The AMCELL AM machine is available for viewing on the TRIDITIVE booth at Formnext 2018 , Hall 3.0-A28.