Success for Metal Injection Moulding at the MPIF’s PM Design Excellence awards

June 15, 2016

Award winning parts in the Metal Powder Industry Federation’s 2016 Powder Metallurgy Design Excellence Awards competition were announced at POWDERMET2016, Boston, USA, June 5-8.

Metal Injection Moulded parts once again dominated the awards, accounting for more than half of the award winners and these parts are reviewed below. To view the complete list of all 2016 award winning parts, including those produced by conventional Powder Metallurgy processes, visit the Powder Metallurgy Review website.

Grand Prize Awards

Aerospace/Military: Advanced Forming Technology

The Grand Prize in the Aerospace/Military Category was won by Advanced Forming Technology, an ARC Group Worldwide Company, Longmont, Colorado, USA, for a Metal Injection Moulded front sight base used on the AR-15 rifle.

The MIM-4605 low-alloy steel part is much larger than the typical Metal Injection Moulded part and has a complex geometry. The switch from a part machined from bar stock to the Metal Injection Moulded part yielded cost savings of more than 30%.

Medical/Dental: Parmatech Corporation

The Grand Prize in the Medical/Dental Category was won by Parmatech Corporation, Petaluma, California, USA, for four stainless steel Metal Injection Moulded components used in an articulating endoscopic surgical device designed specifically for thoracic surgery.

The parts, an articulation lock bar, articulation connector, articulation drive block and knife guide, feature complex geometry that would be extremely difficult to machine. The Metal Injection Moulding process saves an estimated 70% of cost over a traditional machining method. The ability of the Metal Injection Moulding process to produce parts of different alloys with tight tolerances enabled the design of a smaller endoscopic device, a critical benefit in thoracic surgery.

Awards of Distinction

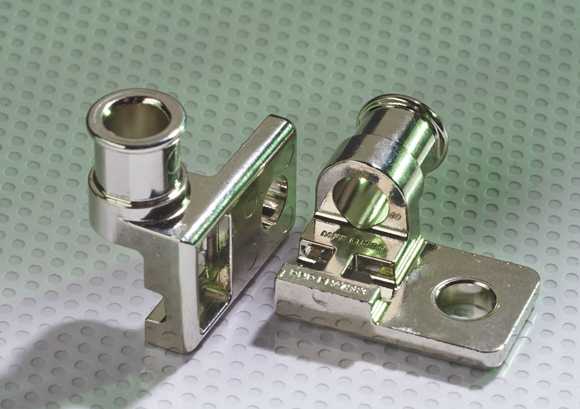

Lawn & Garden/Off-Highway: Indo-US MIM Tec Pvt. Ltd

The Award of Distinction in the Lawn & Garden/Off-Highway Category was given to Indo-US MIM Tec Pvt. Ltd, Bangalore, India, for a Metal Injection Moulded 17-4 PH stainless steel diesel leak-off union made for Lombardini.

The part goes into the fuel injection of a line of Kohler diesel engines that are assembled in JCB midi and mini excavators, compact wheeled loaders and Teletruk forklifts. A conversion from a previously used plastic part whose performance suffered in the tough working environment, the MIM part delivered cost savings of around 10% through improved quality.

Aerospace/Military: Advanced Forming Technology

The Award of Distinction in the Aerospace/Military Category was presented to Advanced Forming Technology, an ARC Group Worldwide Company, Longmont, Colorado, USA, for an aerospace engine ferrule made for its customer Rolls Royce. Made of Metal Injection Moulded 17-4 PH stainless steel, the part provides a conductive path between the screen and the engine, while offering support to the single cable and preventing the placement of cable loading on the screen.

The complex component is sintered exactly to net shape, with no secondary operations needed to meet required dimensional specifications. Cost savings were the primary driver for the switch to a Metal Injection Moulded part from one machined from bar stock.

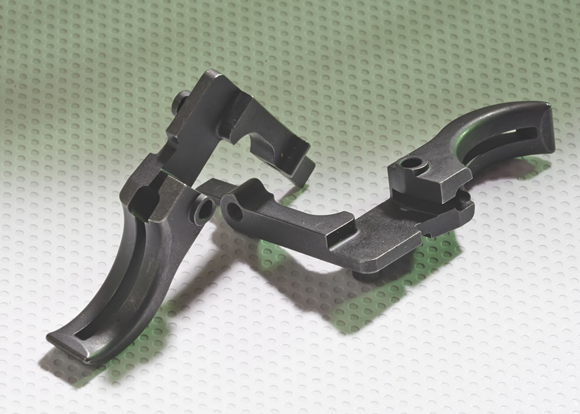

Hand Tools/Recreation: Parmatech Corporation

The Award of Distinction in the Hand Tools/Recreation Category was given to Parmatech Corporation, Petaluma, California, USA, for a MIM 4605 low-alloy steel trigger used in an adjustable trigger system on a pump-action shotgun.

The extremely complex part geometry, which features multiple thickness changes and slots, required precise tooling to address sufficient machine stock for effective secondary operations. The Metal Injection Moulded trigger delivers cost savings of around 50% over the machined version it replaced.

Electronic/Electrical: Indo-US MIM Tec Pvt. Ltd

An Award of Distinction in the Electronic/Electrical Category was presented to Indo-US MIM Tec Pvt. Ltd, Bangalore, India, for three parts, a mirror cover, a base and a middle, made for Optosense.

Moulded from MIM-316L stainless steel, the parts are assembled into an infrared gas sensor for methane and carbon dioxide detection that has extremely low power consumption. A new application designed specifically for the Metal Injection Moulding process, these are medium-complexity parts that have an aesthetic requirement on a few reflective surfaces.

Medical/Dental: Flomet, LLC

An Award of Distinction in the Medical/Dental Category was presented to Flomet, LLC, an ARC Group Worldwide Company, DeLand, Florida, USA for a Metal Injection Moulded tungsten electrode used in a surgical ablation device. The device uses high temperature for the removal of tissue and the use of tungsten enables the electrode to reach its operating temperature more efficiently, maintaining it for a longer time than with other alloys.

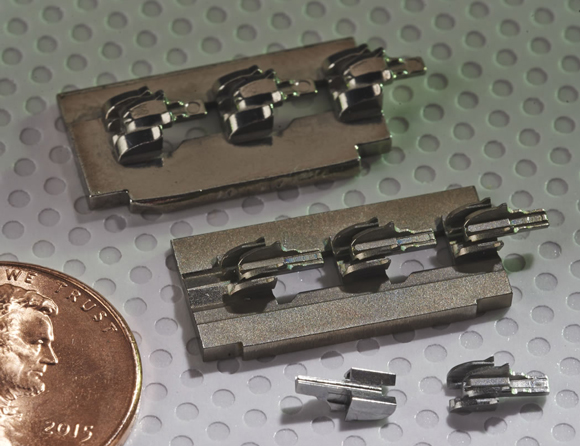

Medical/Dental: Advanced Forming Technology

A further Award of Distinction in the Medical/Dental Category was given to Advanced Forming Technology, an ARC Group Worldwide Company, Longmont, California, USA, for a Metal Injection Moulded wedge blank used in an endoscopic staple gun.

Made from a MIM-440 stainless steel, the part has a complex and very small geometry that pushed the Metal Injection Moulding process to the very limits of tolerance capabilities. The part’s 5 mm diameter, less than half the previous low of 12 mm, enables new procedures to be created and enhances procedures in smaller patients, particularly in the area of paediatrics.