Smith Metal Products adds CNC lathe to expand in-house MIM postprocessing

February 14, 2022

Smith Metal Products, Center City, Minnesota, USA, has extended its in-house machining options with the addition of a new CNC lathe. With this, the company’s post-processing capabilities now include a number of CNC 5-axis machining, CNC turning, coining and laser etching/engraving machines. Smith also has external sources for polishing, lapping, grinding and EDM wire cutting.

MIM is used to produce high volumes of precision parts, often eliminating machining stages due to its near net-shape production process. However, there are some applications where higher tolerances need to be achieved, and for these Smith utilises its CNC machining capabilities.

“We’ve seen a big increase in interest for MIM parts requiring fine tolerances which are beyond MIM moulding capabilities,” stated Jim Beyer, Account Manager. “Secondary, post-process machining is often needed to produce these very precise round holes, threaded holes and smooth, flat surfaces for interfacing with other parts.”

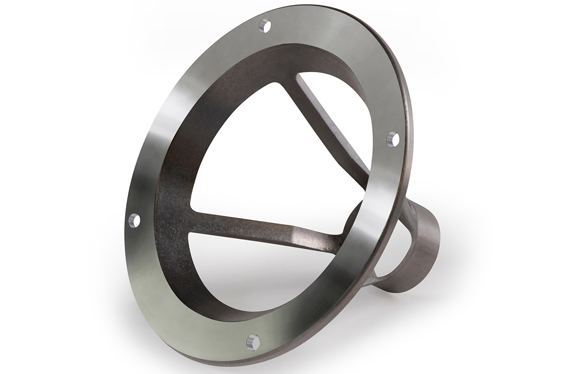

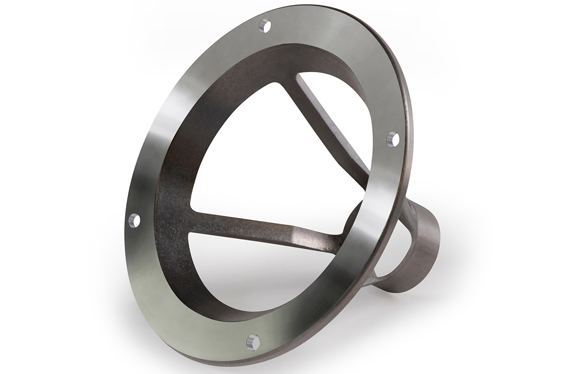

Smith Metal Products produces MIM parts for a variety of industries including automotive, aerospace, firearms, medical, dental, recreation and appliances. Materials processed range from stainless steel, steel, titanium, and most ferrous materials. Parts suitable for MIM at Smith are said to include those that have annual volumes of at least 25,000 pieces for a single component, or three or more parts that have annual usage of 10,000 or more and a finished part weight of less than 100 g.

In addition to its MIM capability, the company offers metal Binder Jetting (BJT) Additive Manufacturing to customers looking to evaluate and verify a product without the cost of building a test mould.