Rise of ‘MIM-like’ processes continues as GE reveals developments

February 16, 2018

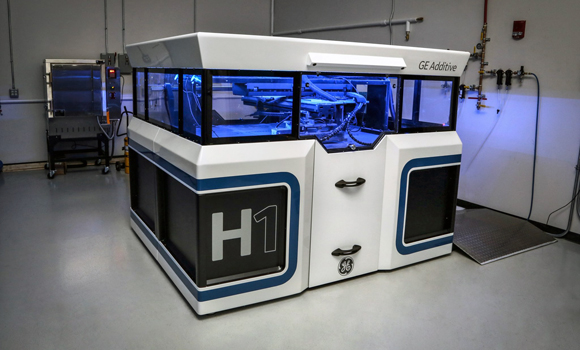

GE’s binder jet system is said to have been developed over just forty-seven days (Courtesy GE Additive)

The seemingly inexorable rise of ‘Metal Injection Moulding-like’ Additive Manufacturing processes appears to be continuing as engineers at GE Global Research, GE Aviation and GE Additive report that they have successfully built and tested thirty different prototypes of a football-sized jet engine component in just twelve weeks. The prototypes were produced on GE Additive’s H1 binder jet AM system, which it states is capable of manufacturing at speeds “ten times faster” than Powder Bed Fusion (PBF) and can be used to produce larger parts.

The part is destined for use in the LEAP jet engine, developed by CFM International, a joint venture of GE Aviation and Safran Aircraft Engines. The original part is said to have taken several years to develop using casting and other conventional manufacturing processes. Using binder jet AM, the engineers were able to design, build and test designs to the required heat and durability standards within a much shorter time-frame.

Compared with PBF manufacturing, binder jet AM consumes much less energy, making the technology more cost effective as well as environmentally sustainable. Arunkumar Natarajan, a senior scientist at GE Global Research and technical lead on the company’s binder jet programme, explains: “Instead of firing high-power lasers over a bed of metal powder, we’re depositing a binder glue like ink on paper.” According to Natarajan, the speed and power of the technology mean it could disrupt the multi-billion-dollar casting industry.

GE is reported to have developed a special binder for its process, which Natarajan states is core to the project’s success. “We’re very excited about the binder jet concept, given the opportunity it provides for faster printing of more parts versus other additive and even conventional manufacturing techniques,” stated Natarajan. “We already have successfully printed several complex metal test parts, using this advanced binder jet process.”

GE’s binder jet system is said to have been developed over just forty-seven days, with the express aim of “challenging casting.” On the first announcement of the machine, Mohamed Ehteshami, Vice President and then-General Manager of GE Additive, stated, “We consume so much casting inside GE. Billions and billions of dollars – and we can disrupt this, not only for ourselves, but for everyone else. We will use this and we will sell this.”

www.ge.com/additive

www.safran-group.com

www.cfmaeroengines.com