Ricoh expands UK Customer Experience Centre with metal Binder Jetting

October 6, 2022

Ricoh Company, Ltd, headquartered in Tokyo, Japan, has announced plans to expand its Customer Experience Centre (CEC) in Telford, Shropshire, UK. This expansion is intended to accelerate co-creation with customers and partners in the Additive Manufacturing industry, particularly those considering using metal Binder Jetting (BJT) for electric vehicles (EVs) and aircraft.

Ricoh hopes to help customers understand the capabilities of its technology while deepening its own understanding of customers’ potential pain points through activities at its CEC. The company will further contribute by providing Additive Manufacturing machines and a total solution for production workflow.

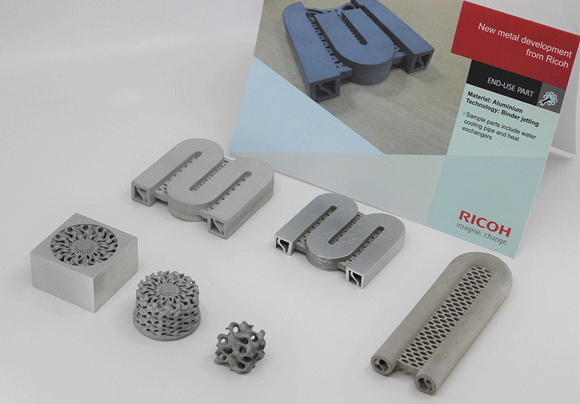

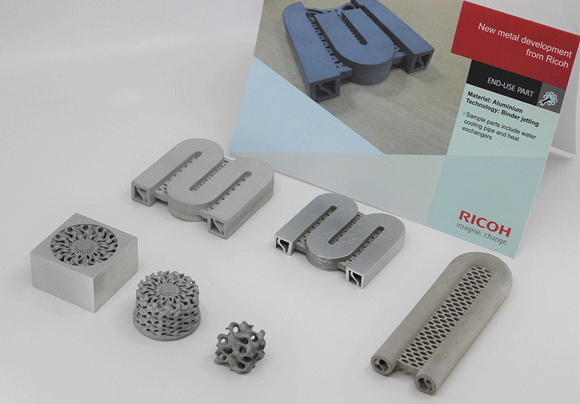

Ricoh stated that its BJT technology is well suited to the manufacture of aluminium parts. The company can utilise its AM technology to produce aluminium parts with complex shapes that cannot be made using existing manufacturing methods, producing lightweight parts, high-performance heat exchange parts, and other components. In addition to heat exchangers, Ricoh has stated that it will explore further applications for aluminium BJT technology with customers.

Ricoh has positioned the ‘realisation of a zero-carbon society’ as one of its key goals. As such, the company is aiming to achieve zero GHG emissions throughout its entire value chain, enabling customers to develop highly energy-efficient products by using Ricoh’s Additive Manufacturing machines.

“There are technical issues with many products where they cannot fully perform due to heat problems or limitation of weight reduction. We are confident that Ricoh’s unique aluminium [BJT] technology will significantly contribute to solving these issues our customers face,” stated Tokutaro Fukushima, General Manager of Additive Manufacturing Business Center, Ricoh Futures Business Unit. “With the opening of the CEC, we would like to accelerate co-creation with our customers to realise additional value for customers’ clients.”

“Furthermore,” he continued, “we would like to actively promote collaboration with technical partners who have unique technologies. We hope to welcome partners who support our vision to ‘Make a significant contribution to a zero-carbon society and lead to the realisation of a wonderful future for children’ through co-creation activities.”