Revolutionary technology could open door to cheaper titanium powder and alloys

January 18, 2008

Although Australia has the world’s largest economic reserves of titanium ore and is a leading exporter, the cost and complexity of processing this ore has deterred the development of a local, integrated, titanium metal industry.

Although Australia has the world’s largest economic reserves of titanium ore and is a leading exporter, the cost and complexity of processing this ore has deterred the development of a local, integrated, titanium metal industry.

However, over the past few years research at the Light Metals Flagship (LMF) – an Australian Government-funded CSIRO initiative involving industry and research partners – a new processing technology is being developed that is said to have the potential to halve titanium processing costs.

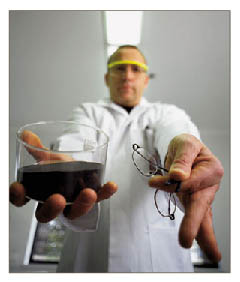

One of the keys to reducing the cost of producing titanium is TiRO™, a new processing technique developed by the LMF. TiRO™ is based on the same chemistry as the Kroll process – the traditional method for producing titanium metal – but is continuous, faster and eliminates many intermediate steps. It directly produces titanium metal in powder form.

In parallel with TiRO™, the LMF is also developing an innovative technology for more efficient and cost-effective production of titanium alloys. Unlike the current technology, which involves mixing, melting and recasting metals, the LMF’s approach is able to directly produce alloys from the raw materials.

‘Technical–economic analysis of our technology predicts a cost reduction factor of 10 compared to current costs of producing such alloys,’ states Dr Jawad Haidar, project leader. The technology – based on reduction of titanium chemicals with aluminium – has produced 150 grams of alloy per hour in a continuous production mode in a small experimental unit. Plans are under way to move up to a larger lab-scale pilot plant.