POWDERMET2019: State of North American MIM industry 2019

July 15, 2019

The POWDERMET2019 International Conference on Powder Metallurgy and Particulate Materials was held in Phoenix, Arizona, USA, from June 23-26, 2019. Organised by the Metal Powder Industries Federation (MPIF), the event attracted over 850 participants and included three days of presentations accompanied by an exhibition and a range of social and networking events.

The Opening General Session included a presentation by MPIF President John F Sweet, PMT, who gave delegates a detailed overview of the state of the North American Powder Metallurgy industry. The 2019 outlook for Metal Injection Moulding was said to remain positive and firm, with estimated 2018 sales of MIM parts in the US increasing by a range of 5–10% ($440–460 million). Sales of MIM parts in China (including Taiwan) were estimated exceeded $1 billion, with European MIM parts sales said to track US sales closely or slightly higher. Total global MIM parts sales in 2018 were estimated at around $2.6 billion.

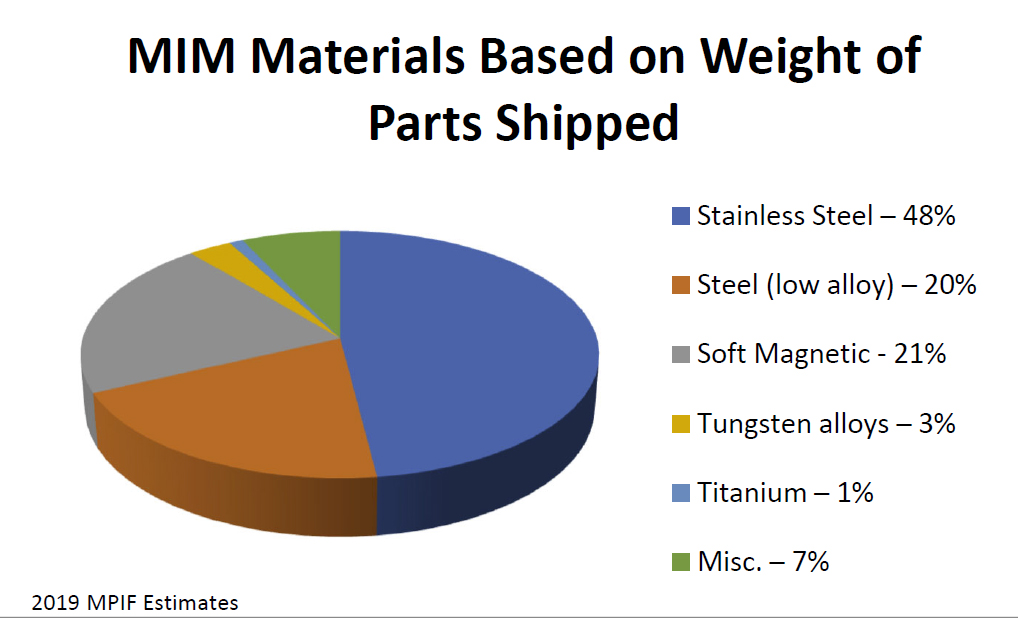

It was stated that MIM-grade fine powders consumed in the US (domestically produced and imported materials) increased by up to 10% in 2018 to 3,465,000 kg (7,623,000 lb). This amount also includes fine powders for metal Additive Manufacturing applications. According to the MPIF PM Industry Pulse Survey, responding members of the Metal Injection Molding Association (MIMA) estimated stainless steel powders accounted for 48% of materials used by weight of MIM parts shipped (Fig. 1).

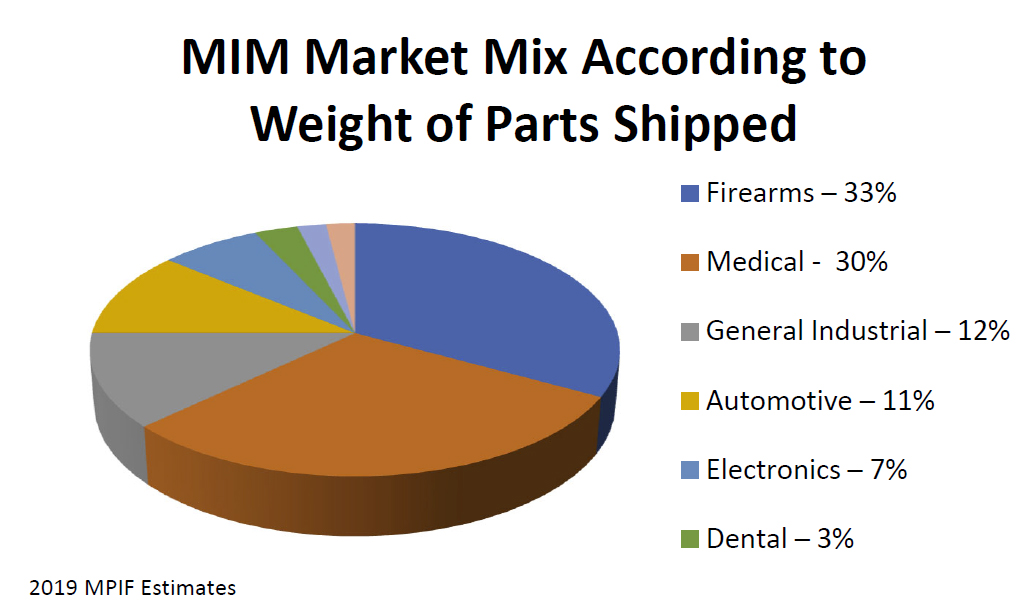

Fig. 2 shows the MIM market mix according to weight of parts shipped. The medical and dental markets will continue growing along with MIM parts in vehicles. The firearms market flattened in 2018, with 2019 experiencing more of the same.

Optimism dominates market expectations for 2019, stated Sweet. The MPIF PM Industry Pulse Survey reports that 72% of MIMA respondents forecast sales increasing and 28% of MIMA members forecast more stable sales levels. The most important reported manufacturing/engineering challenges facing 2019 include reducing time-to-market, expanding capacity, reducing scrap and developing new materials. MIM companies are also actively considering potential manufacturing marriages with AM processes.

Metal powder suppliers, domestically and internationally, are expanding R&D programs and production capacities for a variety metal AM-grade fine powders. They include: cobalt-chrome, titanium, aluminium, stainless steel, low-alloy steel, tool steel and copper, tungsten and tungsten carbide alloys, the Inconel family of materials, and aluminide alloys such as titanium aluminide and nickel aluminides.