ARTICLE: Opportunities in the PIM of Particulate Composites

April 8, 2016

Unique microstructures

Synergistic property combinations, outside the range possible in traditional materials, are important attributes for particulate composites. In particulate composites, there is much property manipulation possible via changes to the microstructure. Early experiments using conductive and nonconductive phases demonstrated over a trillion-fold change in electrical conductivity with a minor change in composition. Depending on the starting particle sizes, composition, and consolidation cycle, the microstructure might have one phase dispersed in the other, or both phases connected. The change occurs over relatively small composition shift. In other words, large property changes might be possible with small changes in particle characteristics, composition or processing. Best wear properties in tool steels are associated with dispersed carbides, while best thermal properties in copper-tungsten composites are associated with interconnected phases.

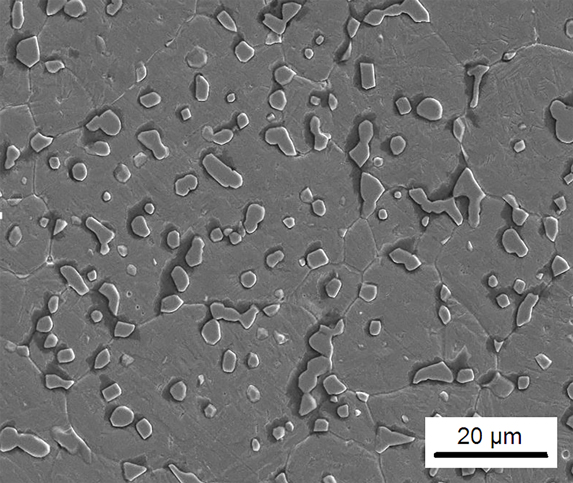

Fig. 2 Microstructure of a sintered Ni-Fe-P composite created from electrolytic coated carbonyl iron powder (Courtesy G. Cui)

An example dispersed phase structure is shown in Fig. 2, the microstructure of a sintered magnetic composite formed using carbonyl iron powder coated with nickel phosphate. The composition is Ni-43Fe-4P. After sintering in vacuum at 1025°C for 60 min, the composite has a density of 7.55 g/cm³ and magnetic properties equivalent to MIM Fe-50Ni, but the hardness is over 350 HV. The compressive strength is 1100 MPa with 19% strain to fracture. As an example of continuous phases, Fig. 3 shows the microstructure of a W-5Ni-2Fe alloy sintered to produce large connected tungsten grains in a continuous alloy phase. The phases are intertwined in three dimensions. While tungsten is brittle at room temperature, the composite exhibits 30% fracture elongation. This is a case of high density and high toughness. The composite has a density of 17.7 g/cm³, tensile strength of 930 MPa, with a hardness of 280 HV. The tough alloy phase between the tungsten grains (nominally 53% Ni, 23% Fe, 24% W) offsets the brittleness expected with such a high tungsten content. The composite is a favourite in radiation containment, inertial devices, self-winding watches, golf clubs, gyroscope components, fishing weights, ammunition and eccentric vibrators. Many of these are large applications, reaching production levels of hundreds of million parts per year.

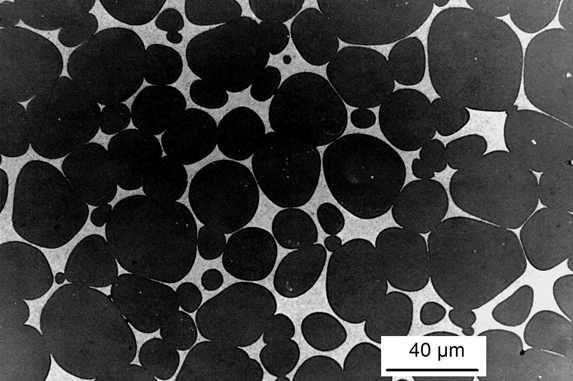

Fig. 3 Tungsten heavy alloy composite microstructure where the dark grains are tungsten and the matrix is an alloy of nickel-iron-tungsten

As an example of continuous phases, Fig. 3 shows the microstructure of a W-5Ni-2Fe alloy sintered to produce large connected tungsten grains in a continuous alloy phase. The phases are intertwined in three dimensions. While tungsten is brittle at room temperature, the composite exhibits 30% fracture elongation. This is a case of high density and high toughness. The composite has a density of 17.7 g/cm³, tensile strength of 930 MPa, with a hardness of 280 HV. The tough alloy phase between the tungsten grains (nominally 53% Ni, 23% Fe, 24% W) offsets the brittleness expected with such a high tungsten content. The composite is a favourite in radiation containment, inertial devices, self-winding watches, golf clubs, gyroscope components, fishing weights, ammunition and eccentric vibrators. Many of these are large applications, reaching production levels of hundreds of million parts per year.

To read the full article, free of charge, download the March 2016 issue of PIM International

- Previous

- 2/2