Novel hybrid Additive Manufacturing process for complex ceramics

May 26, 2023

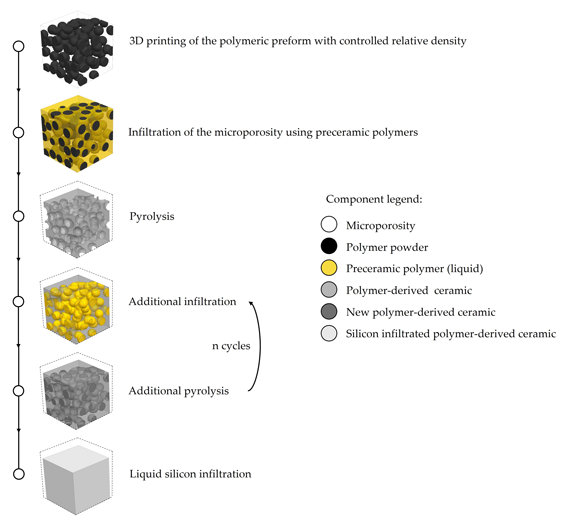

In a recent PhD project at the SUPSI University in Switzerland, material engineer Marco Pelanconi developed a novel hybrid Additive Manufacturing process to fabricate complex ceramic structures. The approach involves the Additive Manufacturing of polymeric preforms with high microporosity through Laser Beam Powder Bed Fusion (PBF-LB), combined with infiltration with preceramic polymers.

Following the Additive Manufacturing stage, pyrolysis is used to obtain a polymer-to-ceramic conversion at around 1000°C. A final densification is performed via molten silicon infiltration to achieve ceramic parts with high density.

Pelanconi used the Sintratec Kit, an open parameter polymer PBF-LB machine from Sintratec, Switzerland. “The Kit allowed us to change a lot of printing parameters, including powder surface temperature, layer thickness, laser speed, hatching spacing, and more, making it easy to control the porosity of the 3D printed parts,” stated Pelanconi.

Varying these factors enabled Pelanconi to achieve an ideal porosity and part quality, said to be crucial for further infiltration.

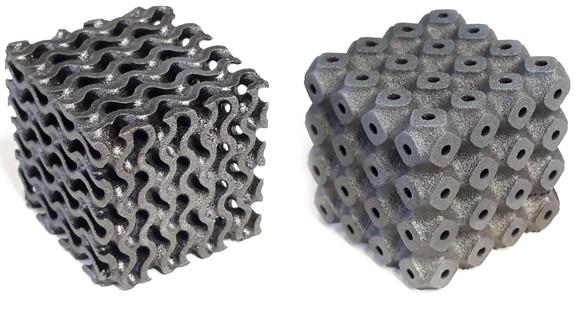

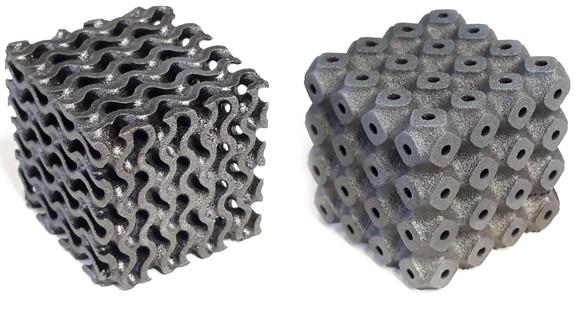

To illustrate how this method could be used for especially complex shapes, Pelanconi’s research focused on two cylindrical porous structures with different topologies: a rotated cube and a gyroid. After Additive Manufacturing with Sintratec PA12 and subsequent conversion into a ceramic, the resulting parts reportedly exhibited outstanding mechanical and thermal properties. They maintained their shape without distortion or macrocracks, despite a shrinkage of ~25%. According to Pelanconi, their impressive biaxial strength of 165 MPa could still be increased through further process optimisation.

Ceramics are well suited to use in extreme environments, such as heat exchangers, catalyst supports, thermal storage, burners or aerospace. The use of Additive Manufacturing to produce complex ceramic architectures is a promising development. “These classes of materials offer unmatched thermo-mechanical properties that cannot be provided by steels, such as high temperature resistance, high oxidation resistance, high thermal shock resistance and high strength,” added Pelanconi.

It was stated that the innovative approach could be exploited by high-tech industries thanks to the many different ceramic materials obtainable from a wide range of preceramic polymers.

Discover more about the Hybrid Materials Laboratory.

Download PIM International magazine