MIM specialist Taisei Kogyo highlights nanoscale porous products and improved surface finishes

August 16, 2017

Japanese Metal Injection Moulding specialist Taisei Kogyo Co. Ltd. has recently highlighted two product application areas that rely on some unique features of the company’s proprietary µ-MIM technology.

The first of these application areas relates to the development of nanoscale porous metal products. Specific surface area is an essential design parameter, for example in electrode or cooling parts, since specific surface area per unit volume affects performance. High specific surface area is a feature of porous metal.

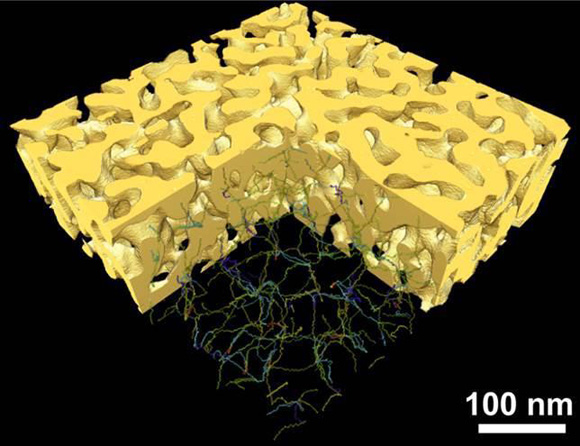

Taisei Kogyo has carried out joint research with Tohoku University Advanced Institute for Materials Research (AIMR) and has established a mass production process for bimodal porous metals with a pore structure consisting of micrometre and nanometre scale pores (Fig. 1). Using this process, a specific surface area of 100m2/g has been achieved.

Fig. 1 Image of bimodal porous metal having specific surface area of 100㎡/g

The second application area relates to achieving fine surface finishes in µ-MIM parts. A satin or matte finish is generally considered to be the standard finish of MIM product surfaces; however, if smaller or finer metal powders are used, smoother surfaces can be realised.

According to the company, feedstock preparation, injection moulding and sintering deformation control are all made more challenging with finer metal powders. Despite these considerations, the company has successfully developed its µ-MIM technology to utilise single-μm or sub-μm metal powder in mass production.

Using this process, the surface finish parameters achieved can be as low as Ra = 1 µm and Rz = 7 µm.