Award winning PIM products

MPIF award winning MIM parts 2007

MIM producers featured extensively in the winners’ list of the Metal Powder Industries Federation’s (MPIF) 2007 ‘Powder Metallurgy Design Excellence Awards’ competition. The awards were presented during the 2007 International Conference on Powder Metallurgy and Particulate Materials held in Denver, 13–16 May 2007. The following award winning parts represent the latest advances in commercial MIM part production.

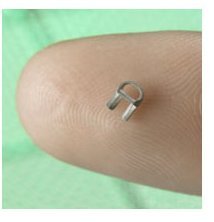

Orthodontic bracket, slide and removable drop-in hook

Flomet LLC, DeLand, Florida, USA and its customer Ormco Sybron Dental Specialties, Orange, Calif., USA, won the MPIF Grand Prize for three parts – bracket, slide, and removable drop-in hook – used in the Damon 3MX self-ligation orthodontic tooth positioning system.

Flomet LLC, DeLand, Florida, USA and its customer Ormco Sybron Dental Specialties, Orange, Calif., USA, won the MPIF Grand Prize for three parts – bracket, slide, and removable drop-in hook – used in the Damon 3MX self-ligation orthodontic tooth positioning system.

One bracket and one slide go on each tooth with the hook an option for about 5% of the teeth. The very tiny, intricate parts are made by MIM from 17-4 PH stainless steel powder to a density of 7.5 g/cm3.

They have impressive physical properties: a tensile strength of 172,000 psi and yield strength of 158,000 psi. All of the parts are made to a net shape. The customer tumble polishes them and performs a brazing operation before assembly.

Trigger Guard

Megamet Solid Metals Inc., Earth City, Mo., USA, won the ‘Hand Tools/Recreation’ category for a rifle trigger guard made by MIM for Modern Muzzleloading, Inc., Alabama, USA.

Megamet Solid Metals Inc., Earth City, Mo., USA, won the ‘Hand Tools/Recreation’ category for a rifle trigger guard made by MIM for Modern Muzzleloading, Inc., Alabama, USA.

The MIM guard supports the trigger group and hammer in the “quick detachable trigger” mechanism in a 50 caliber muzzle-loading hunting rifle. Produced to a density of 7.4 g/cm3, the 88g MIM steel part has an as-sintered tensile strength of 94,250 psi and a 58,000 psi yield strength. The part is held to critical dimensions of +/- 0.005 inches.

Secondary operations include reaming three holes, tapping two screw holes, and deburring. The customer applies the black oxide surface finish and drills one hole because of a design change. It is claimed that the MIM process offered substantial cost savings.

MIM parts for hinge-style handcuffs

SSI Technologies, Inc., Janesville, Wis., USA, won the Award of Distinction for MIM and powder metallurgy (PM) parts used in tactical hinge-style handcuffs made by ASP, Inc., Appleton, Wis. USA, a law enforcement products supplier.

SSI Technologies, Inc., Janesville, Wis., USA, won the Award of Distinction for MIM and powder metallurgy (PM) parts used in tactical hinge-style handcuffs made by ASP, Inc., Appleton, Wis. USA, a law enforcement products supplier.

The handcuffs use 14 PM parts, of which five are different designs—a lock pawl, bow, side and center links, and main links.

Twelve parts are made from three stainless steel materials and two parts are made from MPIF FD-0405-60 steel. The four main links are made by metal injection molding to a minimum density of 7.5 g/cm3 and have a tensile strength of 78,000 psi. The other parts are processed by conventional or high-temperature sintering.

The bow has a tensile strength of 103,000 psi, and has a large 0.090 inch radius in the areas where it touches the wearer’s wrist. These radii had been machined in the previous design. Three modified 316 stainless steel parts and two duplex stainless steel MIM parts make up the linkage assembly. A proprietary and patent-pending design allows the assembly to be swaged together without using rivets. The stainless steel parts meet stringent government corrosion resistance requirements.

Medical pin shroud implant device

Kinetics, a Climax Engineered Materials Company, Wilsonville, Ore., USA, has earned the Award of Distinction for a 316L stainless steel metal injection molded pin shroud made for ArthroCare Corporation, San Juan Capistrano, Calif., USA,

Kinetics, a Climax Engineered Materials Company, Wilsonville, Ore., USA, has earned the Award of Distinction for a 316L stainless steel metal injection molded pin shroud made for ArthroCare Corporation, San Juan Capistrano, Calif., USA,

The critical part is used in the company’s Opus Magnum Knotless Implant device for arthroscopic surgical repair of torn rotator cuffs. The implant device secures a sutured tendon to the shoulder bone.

The pin shroud is implanted into a patient and is critical to the functioning of the rotator cuff surgical procedure. Made close to a net shape, the MIM pin has a typical density of 7.85 g/cm3, a tensile strength of 78,000 psi, and yield strength of 29,000 psi.

Metal injection molding replaced an assembly made by wire-EDMing three parts and assembling them to each other by laser welding. Choosing the single MIM part reduced the customer’s final assembly time by two-thirds, from 15 minutes to just five minutes per unit.

MPIF Grand prize winner 2006

Intricate metal injection moulded parts, a flip slider and hinge barrel, produced by Advanced Materials Technologies Pte Ltd, Singapore, won the grand prize in the electronic/electrical components category of the 2006 Metal Powder Industries Federation (MPIF) awards.

Intricate metal injection moulded parts, a flip slider and hinge barrel, produced by Advanced Materials Technologies Pte Ltd, Singapore, won the grand prize in the electronic/electrical components category of the 2006 Metal Powder Industries Federation (MPIF) awards.

The parts are made using 17-4 PH stainless steel sintered to a density of 7.6 g/cm3.

The parts are made using 17-4 PH stainless steel sintered to a density of 7.6 g/cm3.

Properties include: UTS of 1,185 MPa, YS of 1,090 MPa, 6% elongation, and 30 HRC hardness.

The MIM parts make up the dual-hinge opening mechanism in Motorola’s PEBL mobile phone. The innovative design positions the clamshell phone cover to slide down and flip open in a single movement.

The MIM parts make up the dual-hinge opening mechanism in Motorola’s PEBL mobile phone. The innovative design positions the clamshell phone cover to slide down and flip open in a single movement.

The MIM process allowed a very complex thin wall, overhanging structures and three-dimensional design.

Both parts are coined, machined, polished and plated. Machining these parts, an alternative fabrication method, would have cost five times more than MIM.

EPMA Award of merit 2005

OBE Ohnmacht and Baumgärtner GmbH of Ispringen, Germany, received a 2005 award in the PM Components Category for its metal injection moulded spring hinge used on Tag Heuer sunglasses.

OBE Ohnmacht and Baumgärtner GmbH of Ispringen, Germany, received a 2005 award in the PM Components Category for its metal injection moulded spring hinge used on Tag Heuer sunglasses.

The design concept for the MIM hinges was to produce parts which do not have the appearance of having been formed in a mould, i.e. without edges and corners. The edgeless hinge movement was designed as two disk-shaped forms that slide over each other.

MIM was found to be the only technology capable of economic manufacture of the close tolerance parts which are finished by tapping, sand blasting, polishing and plating.

EPMA Internatioanl award of merit 2005

Advanced Materials Technologies Pte Ltd of Singapore received the EPMA’s International Award of Merit for its metal injection moulded rotary hinge (shaft and plant) used in clamshell mobile phones.

Advanced Materials Technologies Pte Ltd of Singapore received the EPMA’s International Award of Merit for its metal injection moulded rotary hinge (shaft and plant) used in clamshell mobile phones.

The use of the rotary hinge is said to create more viewing angles in the clamshell phones with a 20 degree freedom of movement that fulfills the function and the inbuilt digital camera.

Highly commended in this category is the new Ancorsteel 4300 grade of low alloy steel powder having excellent strength, hardenability, fatigue and toughness, for high performance PM parts.

MPIF Grand prize winner 2005

A highly complex copper electrical connector made by Advanced Materials Technologies Pte. Ltd., Singapore, and used in a plug and adaptor won the grand prize in the metal injection moulding (MIM) category.

The 8.8 g/cm3 density part has an elongation of 45% and is made for Eubiq Pte. Ltd., also in Singapore at a cost saving of more than 20%.

The plug that contains the MIM copper connectors is a new product used in the electrical appliance industry. The plug can be engaged anywhere along the power track and is ergonomically designed to make direct contact with it. The electrical adaptor with the MIM copper connectors allows existing three-pin plugs to engage the power track.

MPIF Award of distinction 2005

FloMet LLC, DeLand, Florida, and its customer SDS Ormco, Orange, Calif., won an award in the injection moulded (MIM) category for a Damon 3 Molar Buccal Tube, self-ligating orthodontic appliance system used in orthodontic braces.

The system consists of 32 MIM brackets and two MIM slides made from 17-4PH stainless steel, which are heat treated and have an UTS of 1275 MPa, 7% elongation, and a 38–42 HRC hardness range. When in full production, this application is expected to total more than 12 million parts annually. The Damon system is said to shorten adjustment time by dentists.