Lithoz sees record year with its ceramic AM machine sales rising by 30%

January 5, 2024

Lithoz GmbH, located in Vienna, Austria, has reported a record year of growth for its ceramic Additive Manufacturing business, achieving a 30% increase in machines sold and nearly doubling material production compared to 2022.

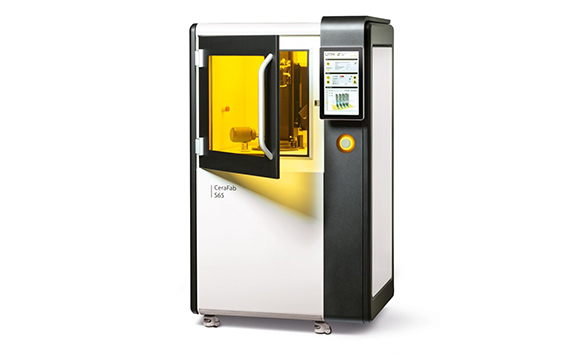

A key focus for Lithoz has been the launch of the Ceramic AM Factory, which uses the company’s Lithography-based Ceramic Manufacturing (LCM) Additive Manufacturing machines for industrial mass production. With a majority of machines this year having been sold to partners with multiple Lithoz systems, serial production has been noted as a ‘clear contributor’ towards Lithoz’s record results.

“By establishing these interconnected machine parks, Lithoz is driving the growth of serial production in ceramic 3D printing,” stated Dr Johannes Homa, Lithoz CEO. “We’re working consistently with our customers to scale up to mass production. With one of our partners now producing well over one million parts per year, it’s fantastic to see all the effort paying off!”

Alongside serial production, Lithoz has focused on developing an ‘all from one source’ portfolio of ceramic Additive Manufacturing solutions. This approach has seen investments into Laser-Induced Slipcasting technology, LSD-Print and Multi Material Jetting (MMJ) via AMAREA Technology.

In 2024, Lithoz has reported that it intends to further support the growth of ceramic Additive Manufacturing by increasing the number and strength of service bureaux worldwide. By establishing machine parks and broadening its offering of ceramic AM solutions, Lithoz intends to advance the Ceramic AM Factory for serial mass production and drive forward industrial applications.

Download PIM International magazine