JPMA award for MIM industrial robot component

December 2, 2019

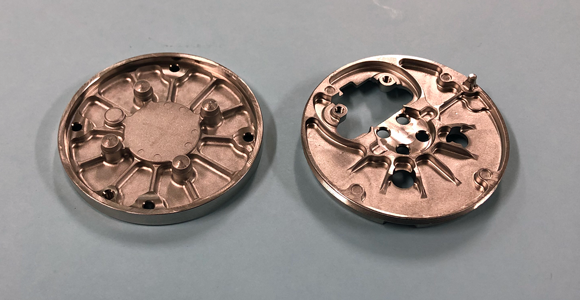

A JPMA 2019 ‘Effort Prize’ was awarded to Fine Sinter Co. Ltd. for the development of a metal injection moulded component used in an industrial collaborative robot. The part requires high accuracy, to less than 0.1% of the nominal dimension, high strength and high corrosion resistance, which had originally led to machined stainless steel being used.

The conversion to MIM had the potential to save material and reduce cost. To manufacture the parts to such a high tolerance, conventional process routes would require a final machining stage. However, the design freedom of the MIM process allowed unnecessary part thicknesses to be reduced, with strengthening ribs introduced as needed. This reduced the overall amount of machining, compared with a fully machined part, by 80-90%.

The market for industrial collaborative robots is expected to grow in the near future due to the increasing need for automation. Offering total cost savings of around 70–80%, MIM has now been adopted for the production of these components.

A full listing of all 2019 JPMA Award winning components is published in the Winter 2019 issue of PM Review.