JEOL’s new electron microscope offers built in automation and live elemental and 3D analysis

January 19, 2022

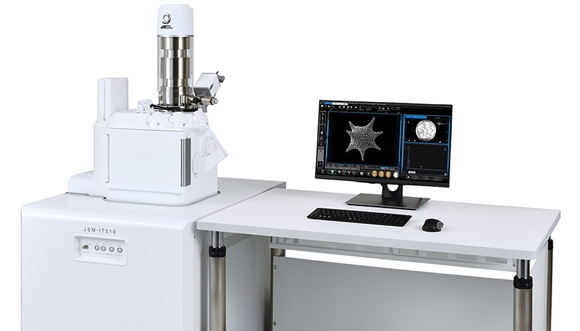

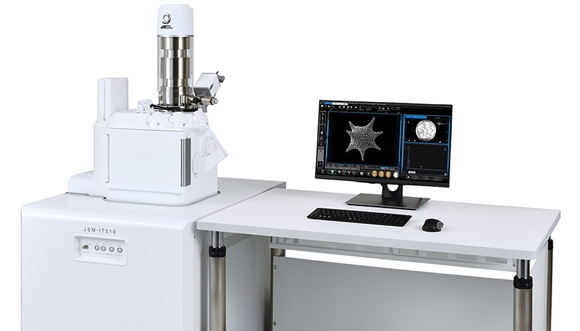

JEOL USA Inc, headquartered in Peabody, Massachusetts, USA, a wholly-owned subsidiary of JEOL Ltd. Japan, has introduced its JSM-IT510, a new scanning electron microscope (SEM) featuring automated imaging, automated montaging (both image and EDS map) and live EDS analysis (spectrum and map).

The IT510 is the successor to the popular JEOL IT500 InTouchScope SEM, with its large sample chamber and tungsten or LaB6 filament. The IT510 features JEOL Intelligent Technology that is reported to enable seamless navigation from optical to SEM imaging, Live EDS and 3D analysis, and auto functions from alignment to focus for fast, clear, and sharp images.

A new Simple SEM function automates image collection at multiple locations on a sample, and sets the various conditions required, including magnification and settings. Simple SEM is said to simplify and automate workflows for routine tasks.

The new Live 3D function constructs 3D images of the sample surface during observation, showing surface shape and depth information in real time. A Signal Depth automated function calculates the X-ray generation depth to support understanding of the analytical spatial resolution within a specimen under the conditions set. Useful when conducting elemental analysis.

A new Low-vacuum Hybrid Secondary Electron Detector collects both electron and photon signals, providing an image with high S/N and enhanced topographic information. This detector also supports photon imaging with specimens that give a cathodoluminescence response.

Live Mapping displays the elemental map simultaneously with SEM imaging, made possible by a new Integrated SEM and Energy Dispersive X-ray Spectrometer (EDS) System. The user can switch seamlessly between the live map view and spectrum view during SEM image observation. Then they can overlay the element maps of interest on the live SEM image for enhancing understanding of element distribution within a specimen.

Zeromag software seamlessly navigates to the area of interest from an optical image of a larger general area of the sample. The user is never lost and can easily navigate to the desired observation area by simply clicking on the optical image.