Innovations from Wittmann Battenfeld as parent group celebrates 40th anniversary

June 16, 2016

Fig. 1 The latest technology on display at Wittmann Group’s 40th anniversary celebrations

The design and production of Wittmann flow controllers in 1976 was the starting point from which today’s Wittmann Group has developed. To celebrate its 40th anniversary, the company invited its customers and business partners to a birthday celebration in Vienna on June 8th and 9th.

Dr Werner Wittmann founded today’s Wittmann Kunststoffgeräte GmbH, based in Vienna, to produce flow controllers. Only three years later, the product range was extended by introducing Wittmann temperature controllers. In 1983, robots were added, followed by the production of dryers, material loading systems, granulators and metering devices.

The takeover of Battenfeld Kunststoffmaschinen GmbH, in Kottingbrunn, Lower Austria, in 2008 was a milestone in the history of the Wittmann Group. Through this move, the company’s previous product range was further extended to include injection moulding machines.

Major investments in product development and an expansion of production facilities for injection moulding machines, automation and peripherals have made the Wittmann Group an important player in the injection moulding arena.

At the 40th anniversary celebrations, following a keynote by Dr Rüdiger Baunemann, Managing Director of PlasticsEurope Deutschland e.V., on Key Drivers for Sustainability, guests were presented with the company’s latest innovations at a private exhibition in Messe Wien. Of particular relevance to the Powder Injection Moulding industry were the company’s new control system and an update to its micro injection moulding system.

Unilog B8 – the new generation of control systems

The new UNILOG B8 control system

Wittmann Battenfeld introduced its new control system generation for the company’s injection moulding machines. The new Unilog B8 sets itself apart from its predecessor with a new 21.5” multi-touch screen and simplified intuitive operation. In addition to soft touch functionality, the company has retained some hard keys in its control system to provide easy access to frequently used functions.

The new control system was in operation on a number of machines in the exhibition area.

MicroPower: multi-component micro injection moulding

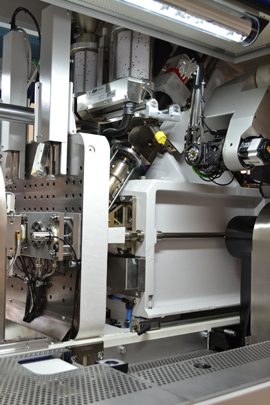

MicroPower in a multi-component version

The MicroPower 15/10H/10H is the first multi-component model of the MicroPower series from Wittmann Battenfeld, designed for the injection moulding of small and micro parts. On this machine, equipped with two parallel injection units and a rotary disk, a 2-component micro part made of POM was manufactured with a single-cavity mould supplied by Ortofon, Denmark.

The machine was also equipped with a fully automatic camera system and a W8VS4 Scara robot from Wittmann for fully automatic parts removal.