Indo-MIM achieves success in MIM category at MPIF PM Design Awards 2019

July 5, 2019

The winners of the 2019 Powder Metallurgy Design Excellence Awards competition, sponsored by the Metal Powder Industries Federation (MPIF), were announced at POWDERMET2019 in Phoenix, Arizona, USA, in June 2019.

Nine Grand Prizes and seven Awards of Distinction were given in this year’s competition, including five Grand Prizes and one Award of Distinction for metal injection moulded components. This year, all of the award winning MIM parts were manufactured by Indo-MIM Pvt. Ltd, headquartered in Bangalore, India.

The six MIM component awards made by the MPIF were as follows:

Automotive: Engine – Turbo Charger Vane

In the Automotive-Engine Category for MIM components, a Grand Prize was awarded to Indo-MIM for a turbocharger vane. The part complexity includes a thin-walled, curved profile with a thick lug on top. A two-drop hot runner tool is used to produce twelve parts per shot without any slide involvement.

Automotive: Chassis – Roof Latching Plate

In the Automotive-Chassis Category for MIM components, a Grand Prize was awarded to Indo-MIM for a MIM-17-4 PH latching plate used in a collapsible roof assembly for passenger cars. A solid-film lubricant coating is applied to the part to reduce friction during operation of the collapsible roof. Moulding was reportedly a challenge, as the part has two thin features joined by a thicker slotted section.

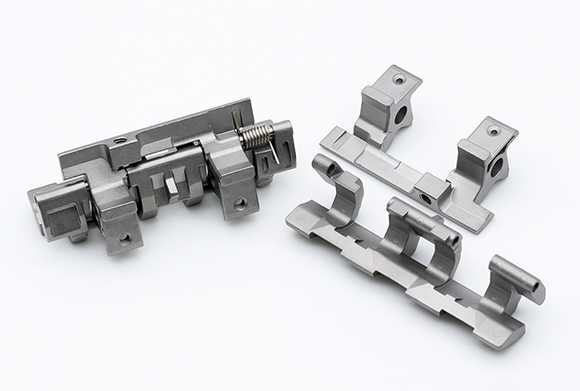

Hand Tools/Recreation – Ski Boot Bindings

The company received the Grand Prize in the Hand Tools/Recreation Category for MIM components for right- and left-hand bindings in ski boots. The parts are made from MIM-4605 that is zinc-blue passivated for corrosion resistance. Previously, the parts were cast and required many secondary operations to meet the desired configuration and dimensional tolerances.

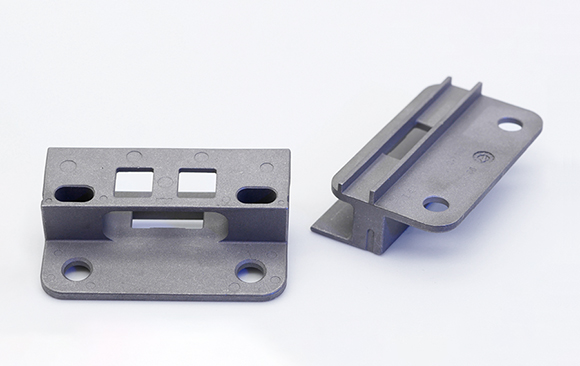

Hardware/Appliance – Door Hinge Keeper/Ramp

A Grand Prize was awarded to Indo-MIM for two MIM-17-4 PH parts, a keeper and a ramp used in a door-hinge assembly. The keeper has a thick but slotted curved profile that extends 79 mm. By using three slides, two to form the hole running along the length, and another to form the slot at the centre, two parts are produced per shot. Previously, the parts were cast and required considerable machining to achieve the desired dimensions.

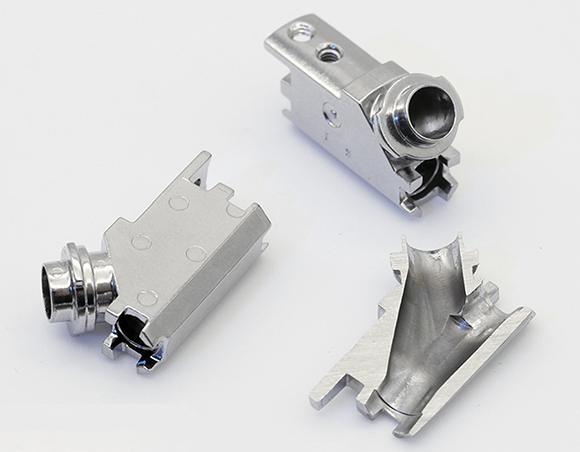

Medical/Dental – Surgical Camera K-Mount

In the Medical/Dental Category for MIM components, a Grand Prize was awarded to the company for a MIM-17-4 PH K-mount main part used in a digital surgical camera. The challenge in moulding was to develop a slide mechanism robust enough to form the y-section with ease and with precise matching to avoid flash. Previously, the part was made as two separate pieces that were subsequently welded. This tended to create sharp edges that damaged the cable during use.

Automotive Engine – Valve Poppet

An Award of Distinction in the Automotive-Engine Category for MIM components was made to Indo-MIM for a valve poppet used in the fuel-injection system of a diesel engine for heavy trucks. The extremely small part has a tight tolerance on its outside diameter and the perpendicularity of the three legs. Part-specific forms were used during sintering to maintain part quality.

View all award winners, including press and sinter PM components, on the PM Review website.