Fraunhofer IKTS introduces Fused Filament Fabrication for hardmetals

October 22, 2018

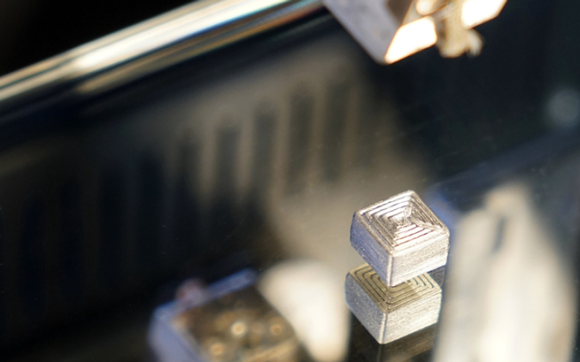

Hardmetal sample with a complex geometry produced on an FFF standard AM system, the Hage3D 140 L (Courtesy Fraunhofer IKTS)

Researchers at the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) in Dresden, Germany, report that they have adapted the Fused Filament Fabrication (FFF) process for the Additive Manufacturing of hardmetals. Extremely hard tools, produced from hardmetals consisting of the metal binders nickel or cobalt and the hard phase tungsten carbide, are required in forming technology, metal-cutting and process engineering.

Cutting, drilling, pressing and punching tools made from hardmetals have conventionally been extruded, metal injection moulded or produced using uniaxial or cold isostatic powder pressing. However, although these methods can achieve a high degree of hardness, they often require complex and expensive post-processing steps to achieve net shape.

Additive Manufacturing enables the production of components with complex geometries with minimal post-processing, but has traditionally been limited in terms of the hardness and component size which can be achieved. Both metal Binder Jetting and thermoplastic 3D printing have been successfully used at IKTS with selected hardmetal compositions; however, the metal binder content and resulting hardness, as well as the size of these components, has been limited.

According to the IKTS, Fused Filament Fabrication could enable economical and customisable production of even harder tools for the first time. Originating in the plastics processing industry, FFF was initially adapted for ceramics and composite materials at IKTS.

During this process, parts are manufactured from a flexible, meltable metal filament. Depending on the material’s structure, a reduced grain size and binder content can be used to specifically increase the hardness, compressive and flexural strength of hardmetal filaments.

Dr Johannes Pötschke heads the Hardmetals and Cermets group at IKTS, explained, “The filaments can be used as semi-finished products in standard printers and, for the first time, make it possible to print hardmetals with a very low metal binder content of only 8% and a fine grain size below 0.8 µm, and thus allow extremely hard components with up to 1700 HV10.”