Fraunhofer IKTS develops innovative two-component (2C) PIM process for a range of unique properties

December 18, 2017

A research team at the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) and led by Dr Tassilo Moritz in Dresden, Germany, has recently been focusing on developing a two-component (2C) Powder Injection Moulding process to produce ceramic components with a unique combination of properties, such as electrical conductivity and electrical insulation, or hardness and ductility, as well as stainless steel–zirconia composites.

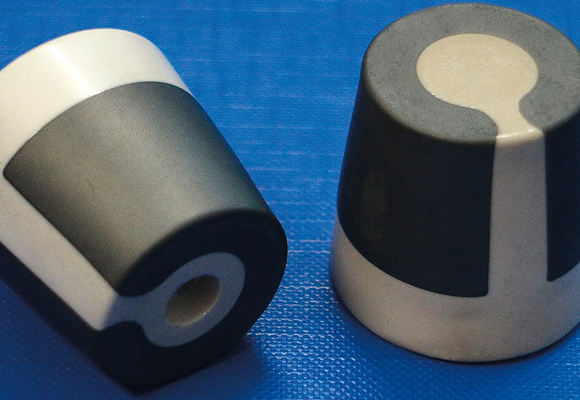

Fig. 1 Two-component injection moulded glass nozzle

Now this 2C PIM shaping method has also been used for combining electrically conductive and electrically insulating sintered glasses. Fraunhofer IKTS states that glass Powder Injection Moulding offers an alternative, powder-based route to conventional glass component manufacturing, which mainly starts from a molten glass. PIM allows for the large-scale production of glass components with complex geometries, structured surfaces and sharp edges without any additional costly grinding or etching steps. The final product properties are attained by debinding and sintering of the powder injection moulded green glass parts, as is the case for ceramic components.

As a special advantage of using the PIM shaping route, additional functionality of the glass component can be achieved through the addition of secondary phases, such as pigments or graphite in powder form. For example, Fraunhofer IKTS has developed an electrically conductive glass component produced by PIM that can be used as a heating element because its ohmic resistance has been attained by the addition of graphite powder. The conductivity of the 2C PIM glass component is said to lie between 300 and 1 Ωcm depending on graphite content.

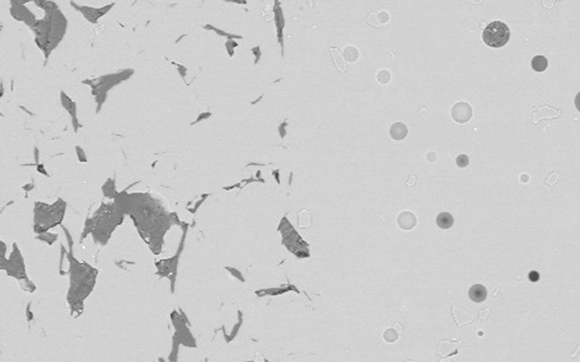

Fig. 2 SEM image of a sintered glass-graphite microstructure

To produce this 2C PIM component two commercially available glass powders (8330 and 8250 produced by Schott AG) were mixed with graphite (KS 15, Imerys) to yield distinct electrical conductivity. Fraunhofer IKTS states that for a successful combination of the two glasses in a subsequent co-sintering process, comparable thermal expansion coefficients and comparable shrinking behaviour were necessary requirements. Shrinkage of the electrically insulating glass component was adjusted by adding alumina powder. The microstructure of a sintered PIM glass composite is shown in Fig. 2.

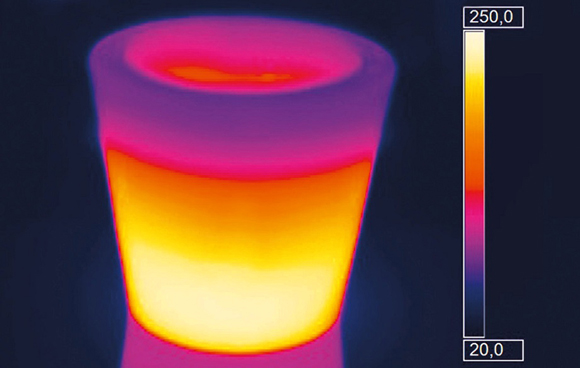

As an outcome of the research project, Powder Injection Moulding was used to manufacture the electrically heatable glass nozzle shown in Fig. 1 and crucible shown in Fig. 3. The homogeneous temperature distribution in the PIM glass composite was detected in infrared tests. In contrast to conventional metal-based components for heating applications, the glass components were found to be significantly more compact and cost-effective. Heatable nozzles and crucibles are shown.

Fig. 3 Thermo-camera image of a heating test of a 2C glass crucible