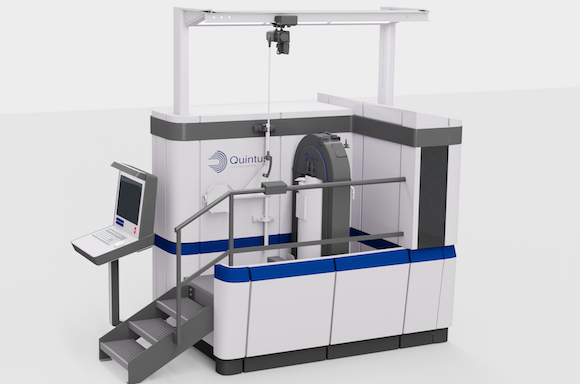

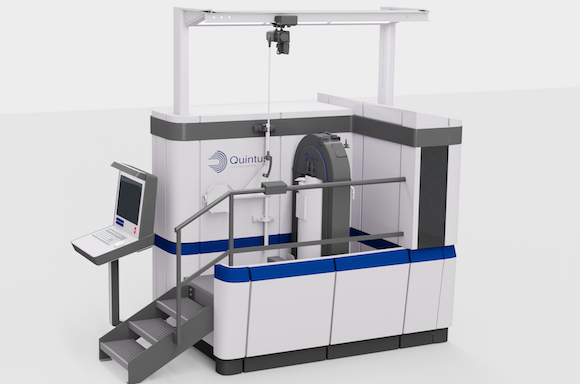

Fraunhofer IFAM to explore future of pressurised heat treatment with Quintus’ HIP QIH 15L system

March 2, 2021

The Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM), Dresden, Germany, has added to its pressure-supported heat treatment options with the acquisition of a Quintus Hot Isostatic Press QIH 15L. The new system is reported to significantly expand the capabilities, which were previously focused on spark plasma sintering technology.

IFAM’s researchers foresee the chief application for the system in the development of combined processes, such as heat treatment and Hot Isostatic Pressing (HIP) for materials with complex heat treatments (e.g., nickel-base superalloys and intermetallic materials).

The new machine is also planned for integration in the institute’s Additive Manufacturing processes with existing HIP treatments optimised and adapted to AM, which involves different microstructures than traditional manufacturing, in order to save significant process time.

The system will be installed in Fraunhofer IFAM’s Innovation Center Additive Manufacturing, ICAM®, where the institute hosts its various AM technologies: selective Electron Beam Powder Bed Fusion (PBF-EB), 3D screen printing, Fused Filament Fabrication, gel casting and MoldJet.

The new system will not only be used for R&D projects, but can also be utilised for carrying out predefined HIP cycles. Customers will have access to a furnace chamber 170 mm x 290 mm, at a maximum pressure of 200 MPa and a maximum temperature of 1400°C. The system is equipped with Uniform Rapid Quench (URQ) technology, which enables cooling rates of up to 10³K/min, making it possible to carry out multi-stage heat treatments in the actual HIP process.