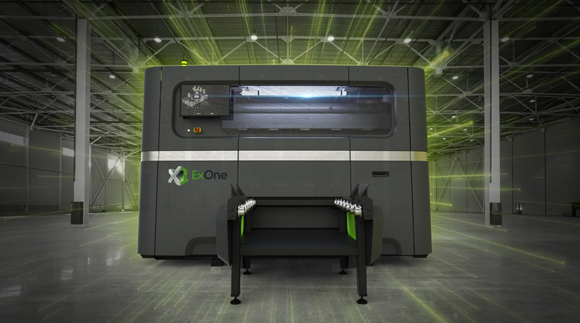

ExOne announces X1 160PRO Binder Jetting system for high-volume production

November 6, 2019

The ExOne Company, North Huntingdon, Pennsylvania, USA, has announced its newest machine and largest metal Additive Manufacturing system to date, the X1 160PRO. Designed for high-throughput and large-part production, the new X1 160PRO will reportedly offer build dimensions of 800 x 500 x 400 mm and build speeds of up to 10,000 cm3/hour.

“Our technology roadmap has been leading us to this machine for more than two decades,” stated John Hartner, ExOne CEO. “At the same time, the X1 160PRO was also designed in response to growing demand from automotive, defence and aerospace customers. We’re incredibly proud of what this model means for the future of metal 3D printing and sustainable production of large metal parts without design limitations.”

Due to ship in late 2020, the open material system will be capable of building in six qualified metals, including the popular stainless steels 316L, 304L and 17-4PH, as well as in ceramics. The X1 160PRO will also feature Industry 4.0 cloud connectivity and process-linking capabilities enabled by Siemens MindSphere.

The new system also incorporates ExOne’s patented Triple Advanced Compaction Technology (ACT) system, said to be critical to delivering consistent part density and repeatability across the entire build area in the binder jet process. Triple ACT is reported to tackle the challenges associated with dispensing, spreading and uniformly compacting ultra-fine metal powders, with an average particle size, or D50, of 9 µm.

The X1 160PRO joins ExOne’s growing family of metal AM systems, which includes the Innovent+, an entry-level system used globally for research, design and small part production, and the X1 25PRO, a mid-size production system which begins shipping this month and will be on show for the first time in Europe at Formnext 2019 in Frankfurt, Germany.