EU funding for AddiFab’s metal and Ceramic Injection Moulding technology

March 3, 2019

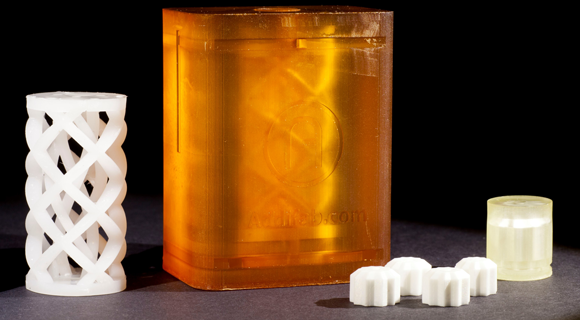

Ceramic and metal injection moulded parts produced using AddiFab’s Freeform Injection Molding technology, with sacrificial thermoplastic mould (centre) (Courtesy AddiFab ApS)

AddiFab ApS, Jylinge, Denmark, has been awarded an EU grant of €1.6 million to boost the commercial readiness of its Freeform Injection Molding™ technology for ceramic and Metal Injection Moulding. The grant is provided under the SME Instrument, part of the European Innovation Council pilot, with funding from the European Union’s Horizon 2020 Research and Innovation programme (grant agreement No 849119).

Freeform Injection Molding is said to combine the short lead-times, low start-up costs and design freedom of Additive Manufacturing with the scalability and use of existing, lower-cost materials offered by injection moulding. It is based on AddiFab’s patent-pending Sacrificial Thermoplastic Injection Molding (STIM) technology, which reportedly allows the production of complex injection moulded components in as little as twenty-four hours.

STIM was used for the first time ever for MIM and CIM in 3DIMS, a project funded by the Danish Innovationsfonden. Same-week delivery of CIM samples was achieved, and a number of metal alloys were processed. The project, which involved the Technical University of Denmark and two Danish companies, also led to the identification of improvement opportunities on usability and scalability expected to make STIM more commercially attractive.

In the STIM-MC (Sacrificial Thermoplastic Injection Moulding-Metal & Ceramic) project, AddiFab aims to implement the improvements identified in the 3DIMS project. Furthermore, the company stated that it aims to demonstrate the commercial readiness of STIM for MIM and CIM through test cases with a number of strategic partners.

AddiFab further announced that Uffe Ditlev Bihlet, PhD, former Specialist and Team Leader at the Materials Business Unit of Force Technology, will be joining the AddiFab team. Bihlet is expected to bring a range of experience in advanced Powder Metallurgy to the project, along with an extensive network from academia and industry.