DSB Technologies adopts Desktop Metal’s complete X-series metal Binder Jetting lineup

September 14, 2023

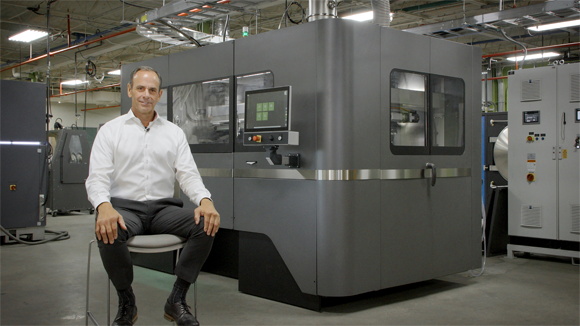

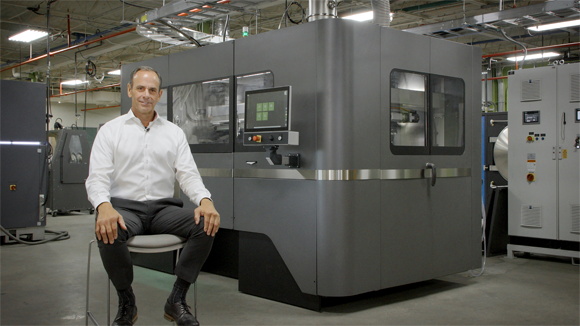

DSB Technologies, a manufacturer of Powder Metallurgy and Metal Injection Moulding components headquartered in Janesville, Wisconsin, USA, has adopted Desktop Metal’s complete X-Series metal Binder Jetting product lineup, including Live Sinter simulation and correction software.

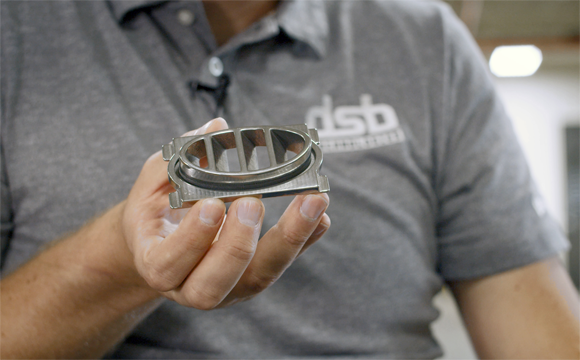

As demonstrated in a new customer video, DSB is currently using Desktop Metal’s InnoventX, X25Pro, and X160Pro machines to develop and deliver customer parts made from a variety of metals, including 316L and 17-4PH stainless steels, 4140, and M2 Tool Steel. DSB also intends to utilise Desktop Metal Binder Jetting technology for aluminium in the future.

“Binder Jetting really is a forming technology that gives us unlimited design potential,” stated Paul Hauck, Chief Operating Officer at DSB Technologies. “We can go from a very simple shape to very complex things you can’t produce in hard tooling, taking complexity beyond what’s possible with Metal Injection Moulding. Binder Jetting creates applications never produced before, and we want to be a leader in that.”

DSB is home to over thirty high-temperature continuous sintering furnaces, which is believed to be the largest installed capacity in North America. Additionally, there is post-processing technology to support volume production in metal Binder Jetting. Out of the 3630 tonnes of metal powder processed by DSB annually, approximately 90% are grades of stainless steel. Currently, DSB serves various markets including aerospace, automotive, defence, electronics, industrial, medical, and sports equipment.

“The exciting part about Binder Jetting is the path from concept to part is all digital,” Hauck added. “You’re not sending a CAD file over to a tool shop that then creates a reverse image. So, you’re taking as few as eight weeks, and maybe as many as sixteen or twenty weeks, out of that process.”

DSB has gradually implemented Desktop Metal’s Binder Jetting technology over the past few years. The InnoventX lab-sized machine, first installed in 2021, is used for material development and testing initial sintering parameters. The X25Pro, installed in 2022, allows the team to scale those successful tests up to application development in a mid-size machine that is also capable of bridge production. The X160Pro, installed in 2023, offers the largest build volume for taking applications to serial production.

Regarding the addition of Live Sinter software, Hauck explained that is highly effective in reducing iterations and saving time. “We now have very useful scientific analytical tools that enable successful outcomes. It’s helping us solve application problems, get successful outcomes, and get there faster.”

Download PIM International magazine