Desktop Metal qualifies 316L stainless steel for the Shop System

August 24, 2021

Desktop Metal, Inc., Boston, Massachusetts, USA, reports that it has qualified the use of 316L stainless steel for its Shop System™, a metal Binder Jetting (BJT) system designed for use in machine shops. Known for its corrosion resistance, high ductility, and excellent mechanical properties at extreme temperatures, 316L stainless steel is an austenitic stainless steel that is well-suited to demanding environments and applications, such as parts exposed to marine, pharmaceutical, or petrochemical processing, food preparation equipment, medical devices, surgical tooling, and consumer products such as jewellery.

“The launch of 316L for the Shop System is a part of an aggressive and extensive materials roadmap to broaden our AM 2.0 portfolio and address a rapidly expanding set of use cases for our print platforms,” stated Jonah Myerberg, co-founder and CTO of Desktop Metal. “We are fully focused on developing opportunities for our customers to produce parts competitively with conventional manufacturing, and we are excited to be able to extend our binder jetting technology to meet this need and address key existing and emerging killer applications for 316L in the market.”

The Shop System offers a turnkey solution for producing complex, end-use metal parts in a fraction of the time and cost of conventional manufacturing and comparably priced legacy AM technologies. The system includes all the equipment machine shops need to begin BJT—from printing through sintering—and is designed to scale throughput with a range of build volume configurations.

Michael Shreeve, Business Development Manager, Precision Components, Wall Colmonoy Limited UK, commented, “Wall Colmonoy is excited to have 316L as a new option for the Desktop Metal Shop System. We look forward to opening up the additive route to many more customers and component types. This will be of particular interest to our customers as we support them with maintaining supply chains across a wide range of industry sectors, such as petrochemical, power generation, automotive, aerospace and more. As we build upon our existing expertise with wear-resistant alloys such as Colmonoy® and Wallex®, 316L on the Shop System will be a welcome addition to our Additive Manufacturing portfolio of materials.”

Desktop Metal shared the following key use cases for 316L stainless steel parts additively manufactured and sintered using the Shop System:

Bulb nozzle

Custom spray nozzles are often used in chemical processing and with conventional manufacturing methods, such nozzles would typically be cast followed by extensive secondary machining on a five-axis CNC. 316L stainless steel is an essential material for this part because of its excellent material properties, even at elevated working temperatures and while spraying corrosive fluids. Additive Manufacturing 316L stainless steel on the Shop System can reportedly produce the entire order of several hundred nozzles in less than a week with only one secondary thread-tapping operation required, reducing lead times and manufacturing process complexity.

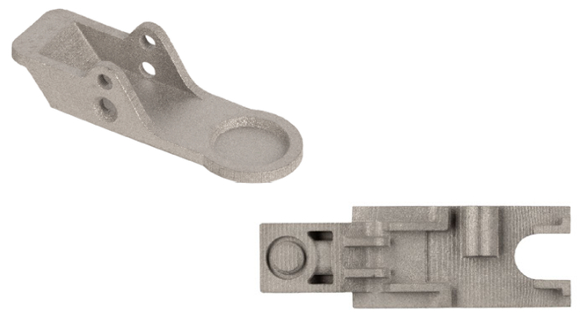

Medical device closure

Assembly closures can be used to latch and hold medical device components in place. CNC machining these closures would be challenging given the precise geometries, while Metal Injection Moulding (MIM) would require large investments and lead times for tooling, difficult to justify given the mid-volume requirements for the component. The Shop System can print up to 10,000 medical device closures in a week, without any tooling costs and without the extensive labour costs and time that machining would require. 316L stainless steel is an ideal material for medical components such as this closure, because of its corrosion resistance, which makes it easy to clean and sterilise.

Watch bezel

A bezel is the main component that houses the dial and movement within a watch. With the Shop System, multiple different watch bezel models can be printed in each build, enabling mass customisation with no tooling required and minimal lead times. For consumer products, applications such as this bezel, 316L stainless steel is an ideal material since it allows for excellent corrosion resistance while maintaining high strength.