Ceramic Injection Moulding used to produce high performance gas turbine components

September 16, 2016

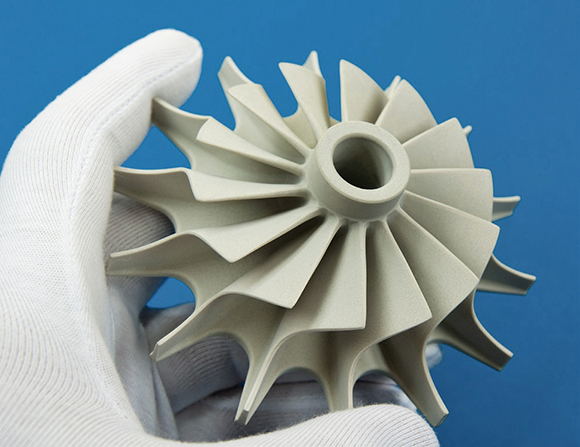

Fig. 1 Radial turbine rotor made by ceramic injection moulding of silicon nitride (Fraunhofer IKTS)

Stationary gas turbines are destined for local and independent energy conversion with combined heat and power generation. Recent research efforts have focused on how the efficiency of these gas turbines can be increased either through using a higher operating temperature or a lower amount of cooling.

Both approaches result in significantly higher gas turbine component temperatures. Because metal alloys are already operating at their physical limits in terms of temperature, researchers are seeking to develop ceramic components capable of substituting metal alloys used at the very high temperatures required.

The recently published Annual Report 2015/2016 of the Fraunhofer Institute for Ceramic Technology and Systems (IKTS), based in Dresden, Germany, contains a review of a research project undertaken by IKTS with four other Fraunhofer institutes where Ceramic Injection Moulding is used to produce radial gas turbine rotors from silicon nitride (Si3N4) powders (Fig. 1). Si3N4 was chosen for the rotors because of its suitability for operating under high thermomechanical loads from room temperature to 1400°C in a micro gas turbine with a capacity for producing 30 kW electricity.

CIM was used to produce the near-net shape rotors because of its suitability for the manufacture of high quantities of components with low loss of material. However, the large volume of the rotor (148 cm3) imposed numerous demands on the mould cavity and the CIM feedstock, with the greatest challenge proving to be the debinding process. This problem was solved by an innovative combination of the chemical and thermal treatment of parts to enable the sintering of defect-free CIM rotors.

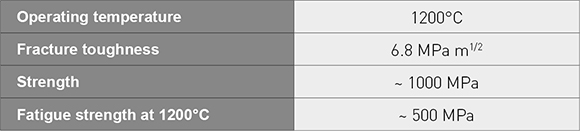

The properties of the micro gas turbine Si3N4 CIM material are shown in Table 1. Fraunhofer IKTS reported that following minor structural modifications the Si3N4 CIM rotors were being installed in the Capstone® C30 gas turbine located at Fraunhofer IFF. Fraunhofer IKTS also reported that it is producing sintered ceramic blades for the first stage of the Klimov GTD 350 helicopter engine that are machined in the green state.

Table 1 Material data for CIM silicon nitride micro gas turbine rotor (Fraunhofer IKTS)