Ceramic Additive Manufacturing market to exceed $3.6 billion by 2028, finds report

October 3, 2018

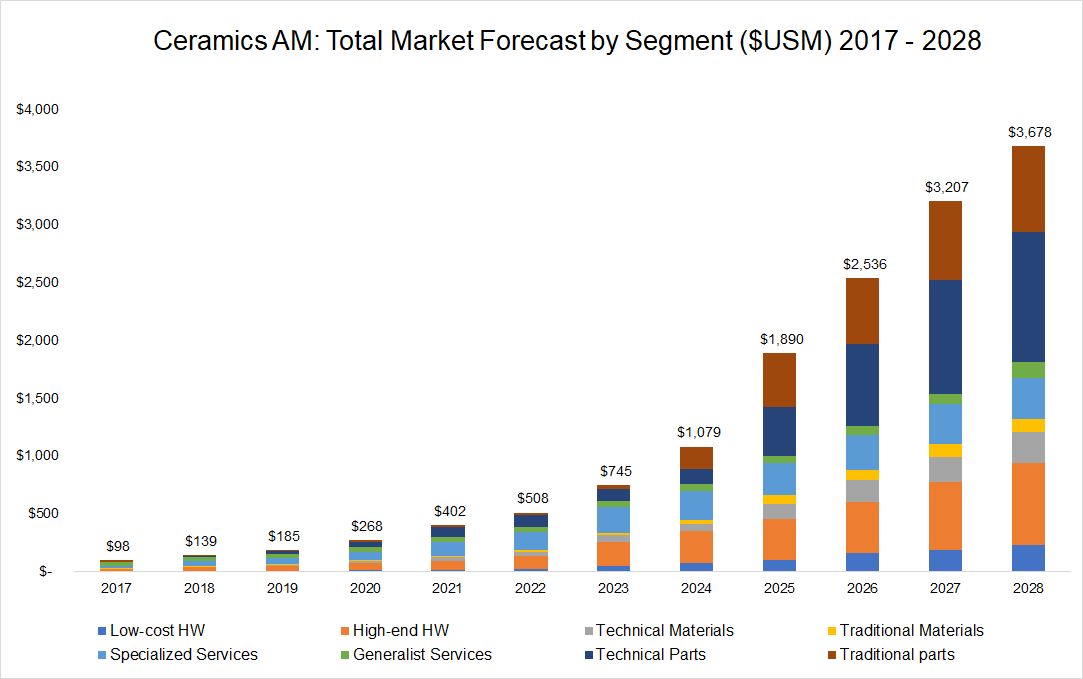

SmarTech’s report forecasts that the ceramic AM market will grow significantly from 2017-2018, driven by strong compound annual growth rates in end-use part production (Courtesy SmarTech Publishing)

Additive Manufacturing industry analysis and consulting firm SmarTech Publishing, Crozet, Virginia, USA, has released the new edition of its study on the emerging ceramic Additive Manufacturing market. The report, ‘Ceramics Additive Manufacturing Markets 2017-2028’, projects that the ceramic AM market will generate overall revenues of over $3.6 billion, driven by strong compound annual growth rates (CAGR) in end-use part production

This is the second report published by SmarTech on the ceramic AM market, and includes up-to-date market data and analysis of market trends at the professional and industrial level. The report breaks down opportunities for ceramic AM across numerous user industries, as well as different AM technologies, materials and material supports, part types and geographical market regions.

The report also analyses some of the pros, cons and revenues generated by the dominant AM technologies for processing ceramics. These include material extrusion, photopolymerisation and Binder Jetting technologies. Currently available high-end industrial system data are complemented by an in-depth analysis of new and emerging technologies such as low-cost hardware systems and new jetting processes, and all analysis is supported with hardware and material market shipments, sales, installations and future forecasts through 2028.

In 2018, SmarTech states, the ceramic AM market is focusing on part production, benefiting from the experience acquired by adopters and system OEMs working with metal and polymer technologies. Ceramic AM, however, presents a distinct set of advantages and challenges, which SmarTech addresses along with the latest successful use cases. Companies developing materials and providing ceramic AM services or specific applications, the firm stated, have come to understand that the excellent geometric capabilities offered by AM can be ideal for the production of complex ceramic parts in all major ceramic adoption segments.

Segments in which ceramic AM is seeing rapid rates of adoption are said to include the aerospace, automotive, marine, energy, electronics, medical, dental and biomedical segments, which have also been among the first wave of adopters of metal and polymer AM technologies. Major companies in the ceramic AM market which are addressed within the report include Lithoz, 3D Ceram Sinto, Admatec, Prodways, Tethon 3D, 3D Systems, Kwambio, Voxeljet, ExOne, HP, Johnson Matthey, Nanoe, XJet and more.

Highlights from the report:

- According to SmarTech’s forecast timeline, ceramic AM adoption will experience an inflection point after 2025 as the major AM technologies that support ceramics production reach maturity and enjoy a sufficient presence in the market to support serial production. SmarTech is currently forecasting that this shift will benefit from imitating the experience of powder-based metal Additive Manufacturing. In particular, the adoption of Ceramic Injection Moulding-based AM processes is expected to drive larger batch production in the same way as the adoption of Metal Injection Moulding-based processes is currently expanding metal AM adoption, by increasing throughput capabilities and lowering costs.

- The final parts value for both technical and traditional ceramic parts is expected to represent the most significant opportunities driving the market for the medium- to long-term future. Compared to the relatively low revenues generated by technical and traditional ceramic materials, SmarTech stated that this trend indicates that in ceramic AM, more than in any other material family, the primary value is in the process. This means that additively manufacturing a ceramic part increases the value of the material used to produce it several times.

- Ceramic AM technologies are now largely available, so perhaps the biggest challenge to address today, according to SmarTech, is the creation of market demand. Many companies that produce ceramic components, especially advanced ceramic components, could benefit significantly from subassemblies and ceramic parts designed for Additive Manufacturing, but in many cases still need to imagine, envision, design and develop the parts that will make ceramic AM processes and materials truly cost effective.

SmarTech Publishing was founded in 2013 and publishes reports on all important revenue opportunities in the Additive Manufacturing industry. The full report on ‘Ceramics Additive Manufacturing Markets 2017-2028’ is available to download via SmarTech’s website.