Boeing issued patent for binderless Metal Injection Moulding technology

May 8, 2019

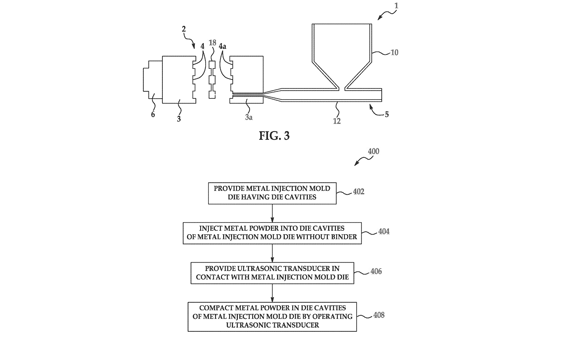

A detail from Boeing’s MIM patent (Courtesy Boeing)

The Boeing Company has been granted a US Patent (20150004047A1, filed September 2014) for what it describes as a binderless Metal Injection Moulding apparatus and method. The patent claims that, without the use of plastic binders, green metal injection moulded parts can be produced devoid of the residual binders found in the conventional MIM process, leading to better dimensional tolerances after sintering.

The patent claims that eliminating the debinding stage will make parts quicker and cheaper to produce than possible with conventional MIM. Although applications for the binderless MIM process are not specified, one of the aims of the process will undoubtedly be to produce components beyond the limitations of current debind/MIM technology, particularly in terms of size and shape.

The new binderless MIM process described in the patent application disclosure involves a fill hopper containing the metal powder, which feeds into an injection conduit linked to a two-part die set containing the die cavities. The powder being fed through the injection conduit is subjected to ultrasonic vibrations imparted by an ultrasonic transducer, which is in contact with the moulding die.

The vibrations are said to facilitate the ‘fluid’ flow of the powder particles into the die cavities in the two-part mould. The ultrasonic vibration of the MIM die is also said to compact the binderless powder to produce the required moulded green part. After moulding, the MIM die can be separated to remove the green parts, which can then be subjected to sintering and/or other post moulding steps. The patent application gives no indication of powder particle size or particle shape suitable for the binderless MIM process.