Award winning parts showcase the capability of Metal Injection Moulding technology

July 3, 2018

Awards of Distinction

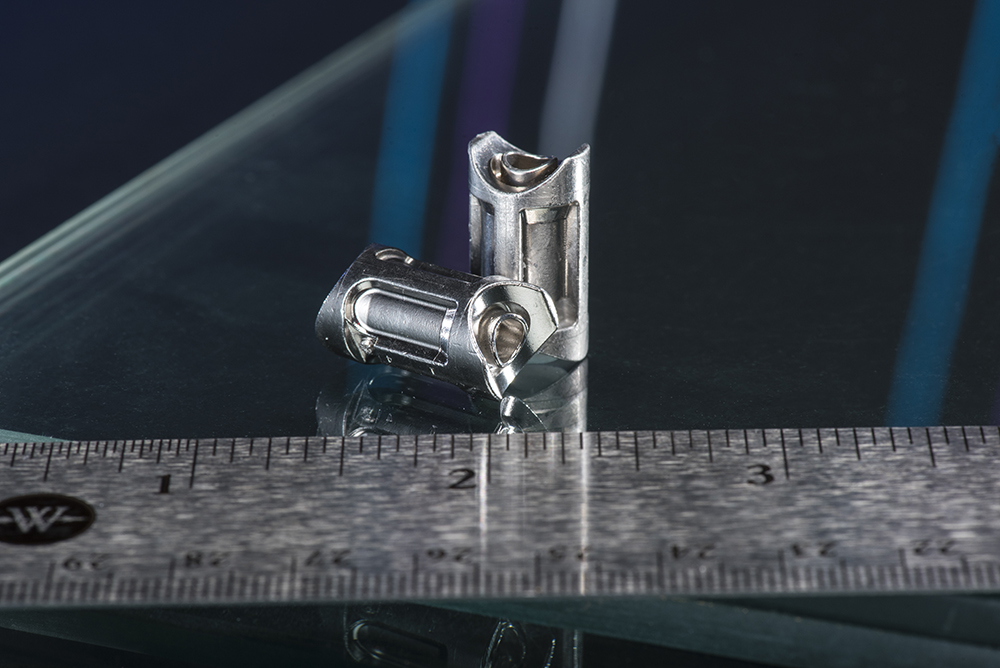

Automotive-Engine: Indo-MIM Pvt. Ltd

Another Award of Distinction in the Automotive-Engine Category was won by Indo-MIM Pvt. Ltd., India, for a MIM stainless steel fuel-inlet orifice used in fuel rail systems of diesel engines in Ford vehicles. The metal injection moulded part is formed close to net shape, requiring only bright annealing to remove surface oxidation and enhance brazing.

The previously machined part was redesigned for MIM in order to overcome the difficulty of producing tapered holes from opposite ends that are free of burrs at their meeting point. The two perfectly aligned holes are achieved using two slides.

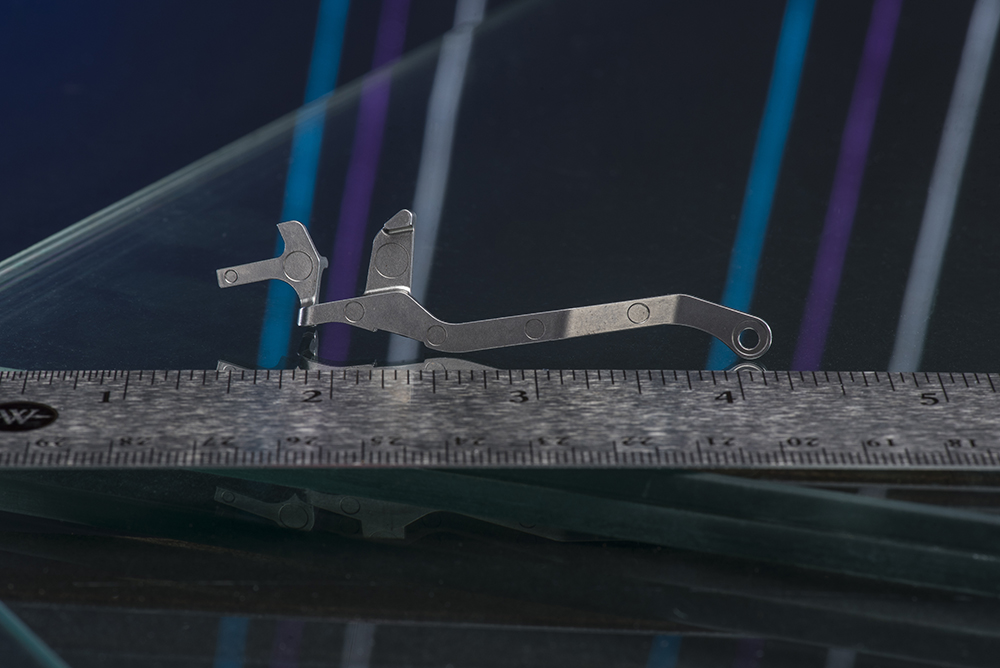

Aerospace/Military/Firearms: ARC Group Worldwide

An Award of Distinction in the Aerospace/ Military/Firearms Category was presented to ARC Group Worldwide for a MIM low-alloy steel trigger bar made for Honor Defense. The nearly 75 mm (3 in) long pistol part is made up of several complex contours with thin cross-sectional areas, making it impossible to hold distortion free through sintering. Several secondary processes, utilising a high-resolution multi-view camera system, were optimised to allow micro-adjustment of each contour to meet the profile requirement, while still delivering cost effectiveness compared with the original machined part.

Aerospace/Military/Firearms: ARC Group Worldwide

A further Award of Distinction in the Aerospace/Military/Firearms Category was presented to ARC Group Worldwide for two MIM stainless steel compensator brakes – a 5.56 and a 7.16 calibre – made for Sig Sauer. The parts are attached to short-barrelled rifles to redirect gases and reduce the effects of recoil. Innovative gating and sintering strategies enabled tolerances to be maintained without secondary sizing or bending operations. In a relatively untapped market for MIM, this new part demonstrates perfectly the complexity, overall size and cost-effectiveness that MIM offers.

Hand Tools/Recreation: Indo-MIM Pvt. Ltd

An Award of Distinction in the Hand Tools/Recreation Category went to Indo-MIM Pvt. Ltd., for a MIM stainless steel passive plus body that goes into a safety assembly of mountaineering equipment. Together with a Kevlar rope and a carabiner to which it is assembled, the part helps to lock the rope in the event of a slip.

Sophisticated shut-offs in the tooling were required in order to achieve the complex internal geometry, which is produced to net shape. A small sizing operation and heat treatment, as well as grit blasting for the part’s finish, are the only secondary operations.

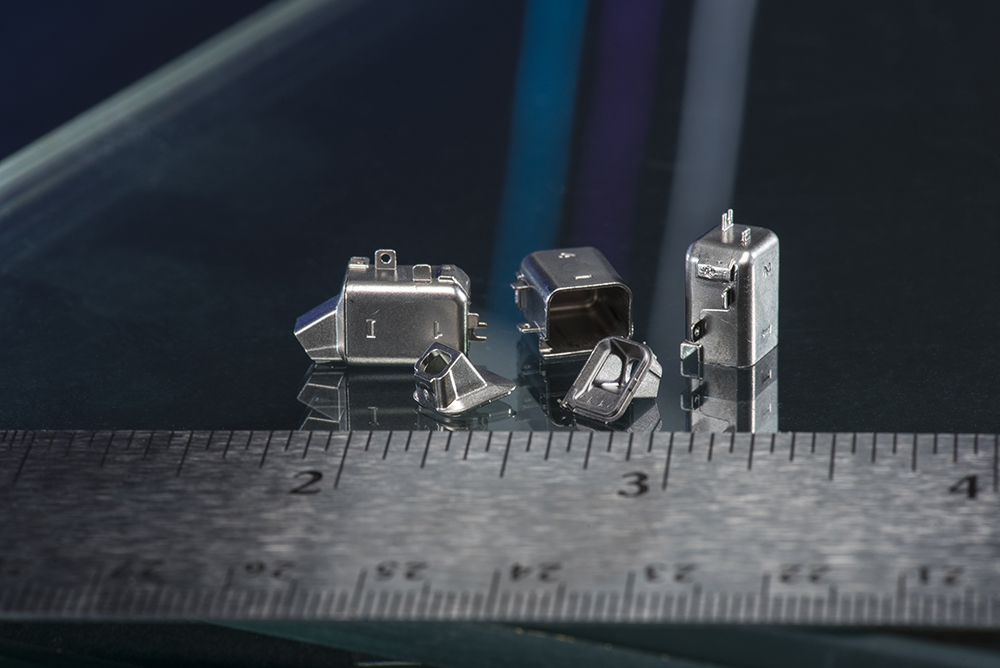

Medical/Dental: Indo-MIM Pvt., Ltd

An Award of Distinction in the Medical/Dental Category went to Indo-MIM Pvt. Ltd., India, for two permalloy parts – a cup and a cover – that are assembled to form a hearing aid enclosure. Both MIM parts are fabricated to near-net shape, with the cup only having a sizing operation to bring its overall dimensions within specification and the cover finish undergoing glass-bead blasting.

The extremely thin walls of the parts, as well as complex features such as holes, pips, and pips with holes, would make this component more difficult and more expensive to produce using any other conventional method.

Electronic/Electrical: ARC Group Worldwide

An Award of Distinction in the Electronic/Electrical Category was presented to ARC Group Worldwide for a MIM stainless steel upper beam handle made for Cutsforth, Inc. The part goes into an EASYCHANGE Removable Brush Holder assembly used in turbine generators in the power industry. Redesigned from a previously 100%-machined part, the as-moulded component, with its many intricate details, needs only one slight machining operation to meet tolerance and functional requirements. The MIM process reduced the per part cost by 60%.

- Previous

- 2/2