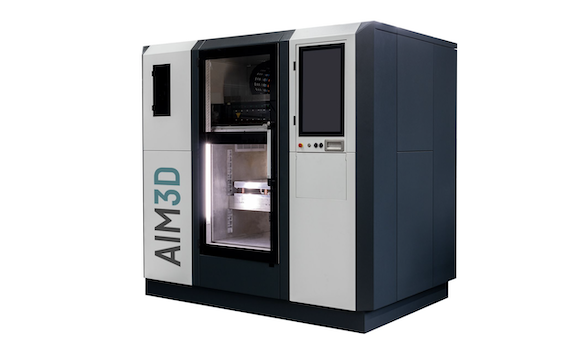

AIM3D premieres ExAM 510 at Formnext 2021

October 27, 2021

AIM3D GmbH, a spin-off company of the German University of Rostock, has developed a new Additive Manufacturing machine for its pellet-based Composite Extrusion Modelling (CEM) process, a Material Extrusion (MEX) process. The new ExAM 510 is a multi-material machine for AM that can additively manufacture up to three different materials in parallel and is suitable for 316L, 17-4PH, 8620, 42CrMo4, 304, 420 W, WcCo, Ti64, Cu99 metals; Al2O3, ZrO2, SiC, Si3N4 ceramics; and plastics.

As the latest addition to the Rostock company’s product offerings, the ExAM 510 machine is intended as a further development of the smaller EXAM 255 model. The multi-material machine can process up to three materials, which allows for two building materials and a support material. The extended build platform of 510 x 510 x 400 mm enables a multitude of applications.

The build area can be heated up to 200°C in order to reduce stresses in the component and to process high-performance materials. It also features a reportedly increased build rate, depending on the material, of up to 250 cm³/h (when using a 0.4 mm nozzle).

The ExAM 510 concept aims to enable significantly increased precision for additively manufactured components. The objective of developing the machine was to get more out of the patented AIM3D extruder technology; this extruder class can enable an output up to ten times higher than standard filament extruders. The use of linear motors and a stable mineral cast bed makes extremely precise operation possible even at high speeds, thus fully exploiting the potential of the technology.

Clemens Lieberwirth, CTO at AIM3D, stated, “The further development of our patented ExAM 255 machine into the ExAM 510 is a technological leap for us. So you could say we are now offering a faster, bigger, hotter and more precise CEM process technology for Additive Manufacturing.”

The ExAM 510 model will be on show as a prototype at Formnext 2021. After a beta phase with pilot processors, AlphaSTAR anticipates that the ExAM 510 will be ready for series production in time for Formnext 2022.