Centorr Vacuum Industries expands its MIM furance offering with a new line of low cost metal hot zone Modular MIM

March 1, 2007

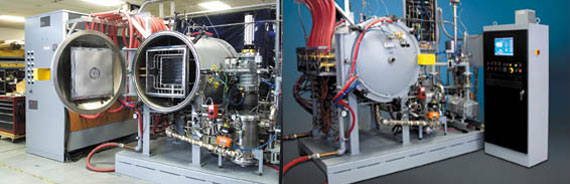

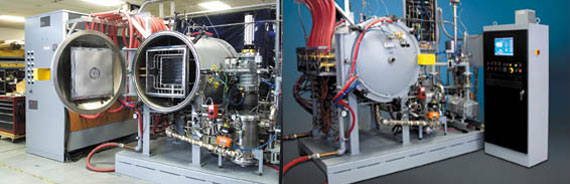

Centorr Vacuum Industries is expanding its furnace offering for the metal injection molding market with the introduction of a new line of Modular MIM-Vac™ custom metal hot zone furnaces, based on industry input concerning features and capabilities. Units have already been sold to customers in Europe and China. The MIM-Vac has a number of design improvements specific for use with MIM feedstocks. These include molybdenum hot zones with integrally designed gas-plenum retorts using Sweepgas™ technology for consistent gas flow dynamics over the parts, compact ‘modular’ furnace layout and construction for fast installation and aesthetics, a dry mechanical pumping system for clean and efficient handling of any binder, and the use of advanced molybdenum alloys in the hot zone and retort offering excellent creep resistance, higher recrystallization temperatures, and longer life.

The new MIM-Vac furnace by Centorr Vacuum Industries, USA

The new line of MIM-Vac™ furnaces is said to offer a temperature uniformity of +/- 5°C, and operates in a partial pressures from 10-750 torr in argon, nitrogen, or hydrogen gas using mass flow controllers for completely automated control. It is available with an easy-to-use HMI software package for computer control. The new MIM-Vac™ is available in sizes from 2, 6.75 and 9 ft3.

For more information please contact Centorr. Tel: +1 603 595 7233.