PM World Congress in Yokohama points the way for next generation in Powder Metallurgy: Part 1, Asia

October 24, 2012

The PM2012 Powder Metallurgy World Congress was held in Yokohama, Japan, October 14-18, and attracted over 700 delegates and almost 7000 exhibition visitors who had come to learn about new global developments in PM technology. Some 500 technical presentations were included in the oral and poster sessions and a lively accompanying exhibition featured 95 PM producers, metal powder suppliers and equipment producers from 15 countries. There were also opportunities to participate in a variety of social events which portrayed traditional Japanese music, customs, culture and cuisine.

The PM World Congress, jointly organised by the Japan Powder Metallurgy Association (JPMA) and Japan Society of Powder & Powder Metallurgy (JSPM) under the auspices of the Asian Powder Metallurgy Asian (APMA), had as its slogan ‘Challenges for the next generation’ and there was indeed much for the next generation, as well as the current one, to ponder over in the Technical Programme.

There are the challenges not only to broaden the spectrum of materials and applications already covered by PM components, powder injection moulding (PIM), hard materials, magnets and hot isostatic pressing, but there are also opportunities to contribute to the development of a host of new technologies. In particular PM can help improve fuel efficiency and reduce emissions of vehicles – the PM industry’s biggest customer.

In the Global Powder Metallurgy Review session which followed the opening ceremony, Kazuyoshi Tsunoda, President of the JPMA reported that China and India had become members of the APMA at the association’s first conference held in Jeju, Korea, in November 2011.

Fig.1 Kazuyoshi Tsunoda, President of the JPMA, presented an overview of PM activities in Asia

Tsunoda stated that China is now the region’s largest PM producer with a total of over 143,000 tonnes of ferrous and non-ferrous PM parts produced in 2011, having overtaken Japan in 2009. He further stated that most of the PM industries in the other countries in the region also showed steady gains in 2011. (Table 1). Fig. 2 shows the steady progression of PM growth in the major industrialised countries of Asia since 2002.

Table 1 Production of PM parts and bearings in Asia in 2011

Tsunoda said that the most recent economic crisis saw PM grade iron powder shipments in Japan slump from around 110,000 mt to below 80,000 mt in 2009, but that the recovery in the global economy helped to boost PM iron powder shipments in 2010. However, the earthquake and tsunami in north east Japan in March last year had a significant impact on reducing demand for PM products over the remainder of 2011.

Fig. 2 Production trends in five PM producing countries in Asia 2002-2011

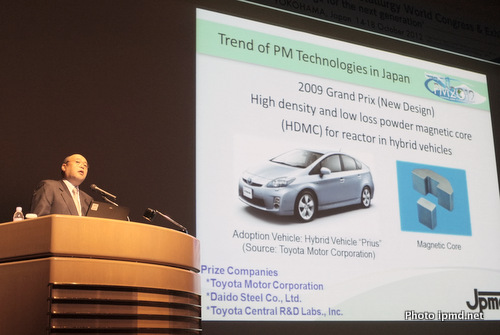

The need for the automotive industry to make vehicles more fuel efficient has given Japanese PM companies the opportunity to develop new applications, and has helped to increase the average weight of PM parts per car to around 10 kg in Japan, said Tsunoda. There is also a strong trend towards electric vehicles (EVs) and hybrid electric vehicles (HEVs) as was illustrated through the development of high density and low loss powder magnetic cores for reactors in Toyota’s Prius.

Tsunoda reported on the Voluntary Action Plan by Japan’s PM industry to reduce CO2 emissions in PM production and also to reduce the amount of landfill waste resulting from PM production. He stated that CO2 had been reduced from a starting point of 2200 kg CO2/ton in 1999 to 2015 kg CO2 in 2010, and that this would be further reduced to 2009 kg CO2 by 2020 (Fig. 3).

This voluntary action has succeeded in reducing waste in PM production from of 20 kg/ton in 2001 to 4.1 kg/ton in 2009, said Tsunoda. A further reduction to 3.1 kg/ton is expected by 2020. (Fig. 4)

Fig.3 Voluntary Action plan to reduce CO2 emission in PM production in Japan 1999-2010

Fig.4 Voluntary Action plan to cut waste products in PM production in Japan 2001-2010

Another successful JPMA initiative are the seminars on ‘Case Studies on Environment and Energy Saving through Production Efficiency’. There have been 166 presentations by JPMA members since 1980 where companies openly discuss how they have succeeded in developing new products to improve the environment or where savings in energy or production efficiencies have made been made. A special JPMA seminar containing case studies in this area was held during the PM2012 World Congress.